| –

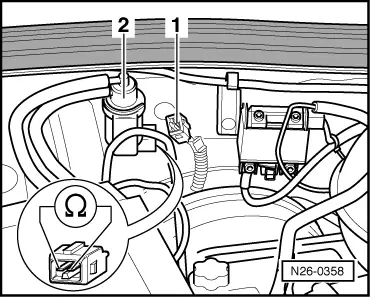

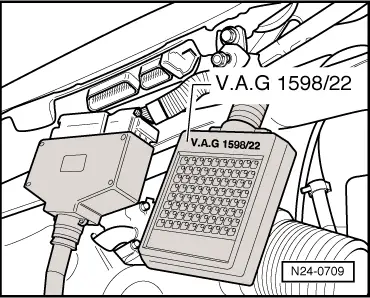

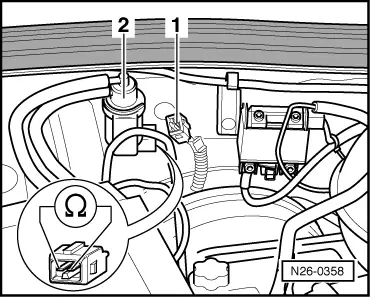

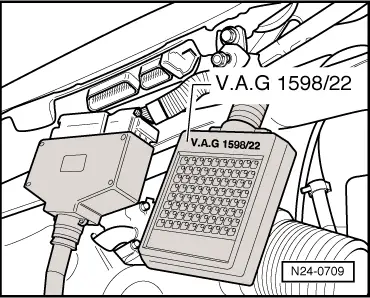

| Connect the -V.A.G 1598/22- checking box to the cable harness of the control unit. |

| –

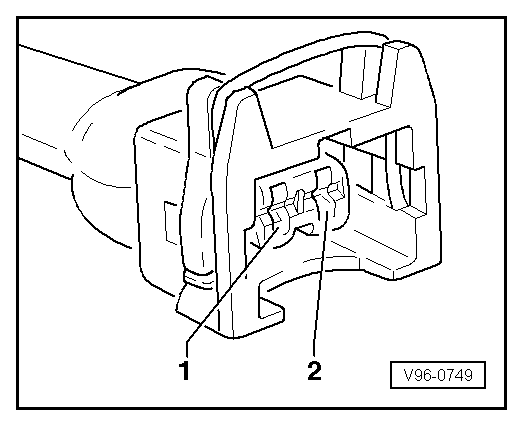

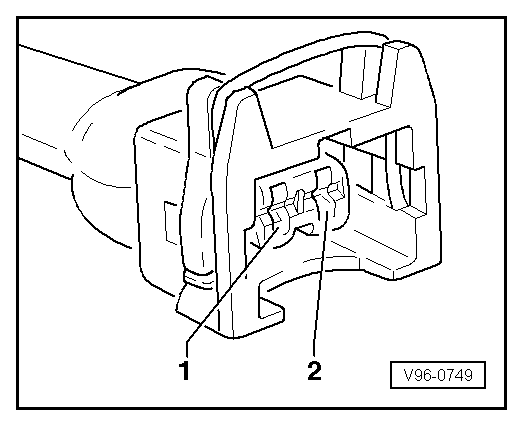

| Check for breakage in the cables between the checking box and the connector, following the current circuit diagrams. |

|

| Cable resistance: 1,5 Ω max. |

| –

| Additionally, check the cables for short circuiting between them, to ground and to battery positive. |

| If no fault is found in the cables: |

| –

| Replace the control unit of the diesel direct injection system -J248-: → Rep. Gr.23 |

|

|

|

Note!

Note!

Note!

Note!