| –

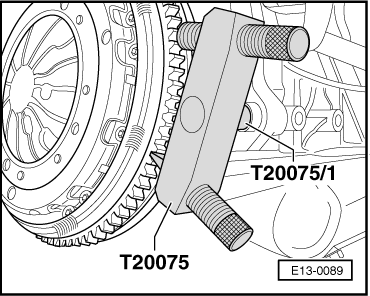

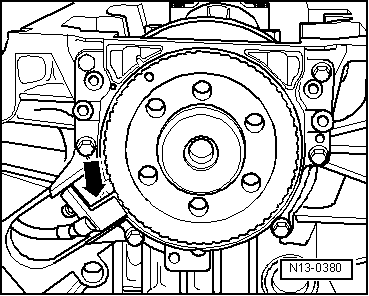

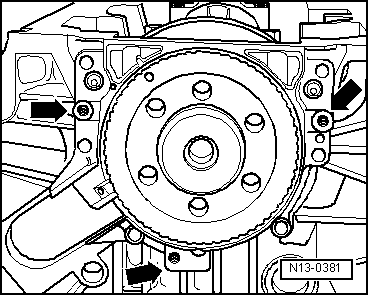

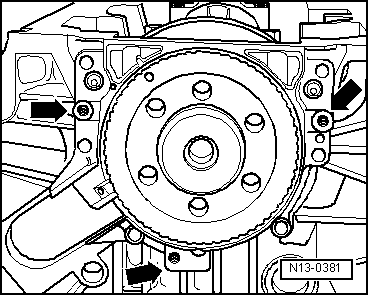

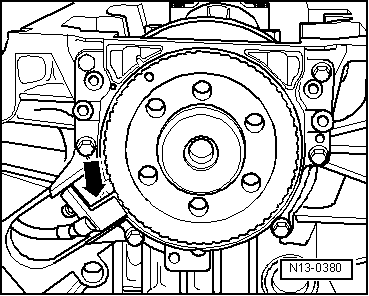

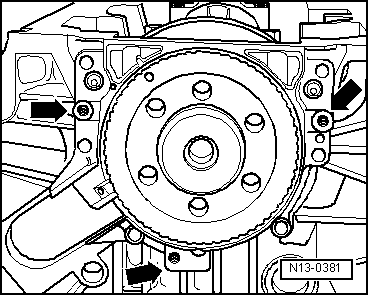

| Screw Qty. 3 M6×35 mm bolts into the threaded holes -arrows- of the sealing flange. |

| –

| Screw in the bolts, alternating between them (max. 1/2 turn (180°) per bolt), in the sealing flange and separate it from the crankshaft together with the sender wheel. |

|

|

|

Note

Note

Note

Note