Leon Mk1

| Piston and conrod removing and installing |

Note

Note| Before carrying out any assembly work, it is necessary to lubricate points of support and sliding surfaces |

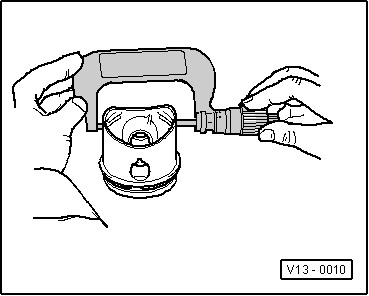

| 1 - | Piston |

| q | Checking → Fig. |

| q | Mark installation position and piston/cylinder correspondence |

| q | Arrow on piston crown points to crankshaft pulley end |

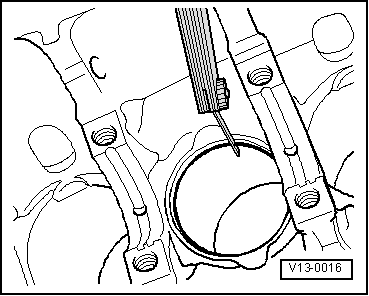

| q | Install using piston ring sleeve |

| q | Piston and cylinder dimensions → Chapter |

| 2 - | Piston pin |

| q | If difficult to move, heat piston to 60°C |

| q | Remove and install with tool -T20019- |

| 3 - | Safety washer |

| q | Renew |

| 4 - | Conrod |

| q | Only renew as a set |

| q | Mark cylinder number -A- |

| q | Markings -B- should face towards pulley end |

| q | Guided axially via piston |

| 5 - | Bearing shell |

| q | Do not interchange used bearing shells |

| q | Place bearing shells in correct position |

| q | Check radial clearance with Plastigage |

| q | New: 0,020 … 0,061 mm |

| q | Wear limit: 0.091mm |

| q | Do not rotate the crankshaft when checking the radial clearance |

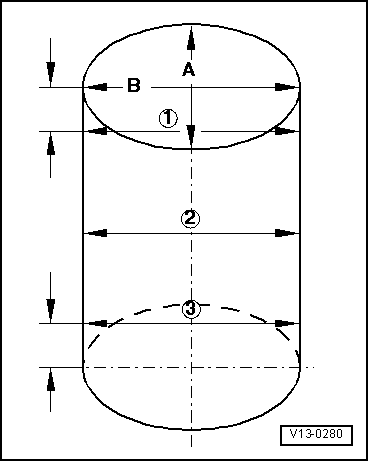

| 6 - | Cylinder block |

| q | Cylinder bores: checking → Fig. |

| q | Piston and cylinder dimensions → Chapter |

| 7 - | Conrod bearing caps |

| q | Note the fitting position |

| q | The caps only fit in one position and only on the appropriate conrod, this is due to the breaking procedure (cracking) separating the cap from the conrod |

| 8 - | 30 Nm + 1/4 turn (90°) |

| q | Renew |

| q | Oil the threads and contact surface |

| q | To measure radial clearance tighten to 30 Nm but not further |

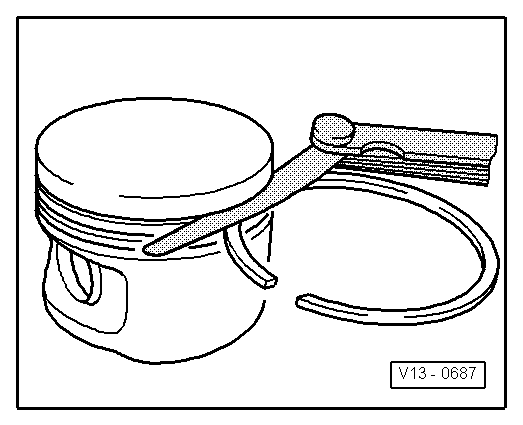

| 9 - | Oil scraper rings |

| q | Carefully remove and install 3-part oil scraper rings by hand |

| q | “TOP” faces towards piston crown |

| q | Ring gap: checking → Fig. |

| q | Ring to groove clearance: checking → Fig. |

| 10 - | Compression rings |

| q | Offset gaps by 120 ° |

| q | Remove and install with piston ring pliers |

| q | “TOP” faces towards piston crown |

| q | Ring gap: checking → Fig. |

| q | Ring to groove clearance: checking → Fig. |

| Piston ring | Wear limit |

| 1. Compression ring | 1.0 mm |

| 2. Compression ring | 1.0 mm |

| Oil scraper ring | 1.0 mm |

|

|

| Piston ring | Wear limit |

| 1. Compression ring | 0.25 mm |

| 2. Compression ring | 0.15 mm |

| Oil scraper ring | 0.15 mm |

|

|

Note

Note

|

|