Leon Mk1

| Ignition transformer -N152- checking |

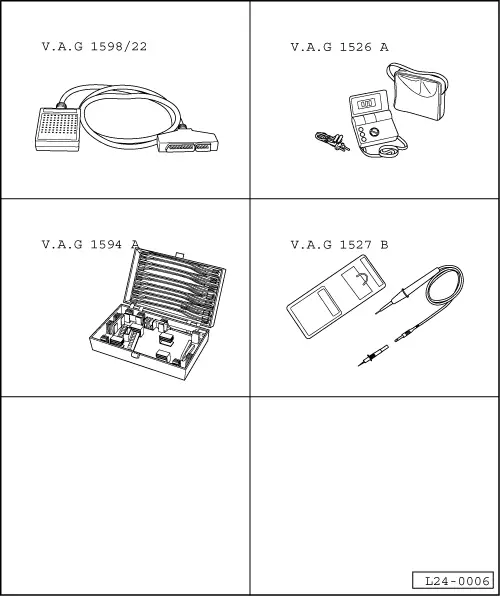

| Special tools and workshop equipment required |

| t | Hand multimeter -V.A.G 1526 A- or multimeter -V.A.G 1715- |

| t | Diode test lamp -V.A.G 1527 B- |

| t | auxiliary measuring set -V.A.G 1594 A- or -V.A.G 1594 C- |

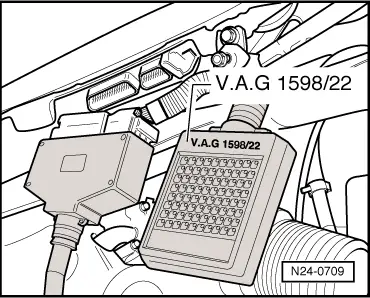

| t | Test box -V.A.G 1598/22- |

| t | Current flow diagram |

|

|

|

|

|

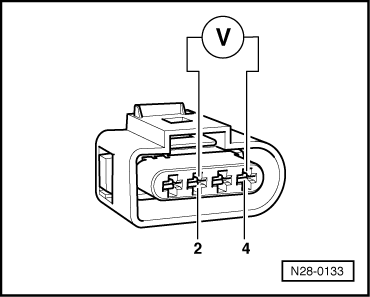

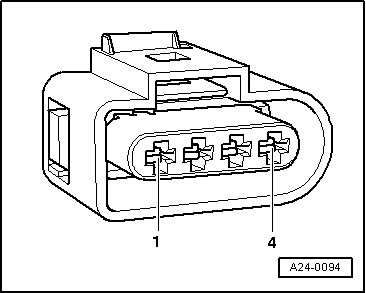

| Connector, contact | Connector, contact |

| 2 | 4 |

| Switch ignition on | |

| Specification: 11.5 V min. | |

|

|

|

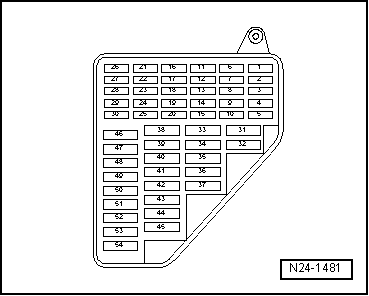

| Connector, contact | Relay plate |

| 2 | fuse 42 |

| 4 | earth |

| Specification: 1.5 Ω max. | |

|

Note

Note

|

|

|

|

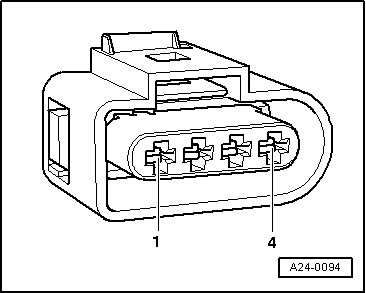

| Connector, contact | Connector, contact |

| 1 (ignition output 1) | 4 |

| 3 (ignition output 2) | 4 |

|

|

|

|

|

| Connector, contact | Test box -V.A.G 1598/22-, socket |

| 1 | 57 |

| 3 | 71 |

| Specification: 1.5 Ω max. | |

|

|

|

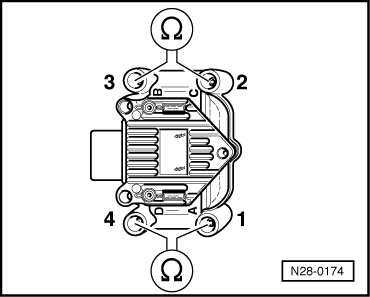

| Cyl. (see illustration) | Cyl. (see illustration) |

| 1 | 4 |

| 2 | 3 |

| Specification: 4.0 … 6.0 kΩ (at 20 °C) | |

|

WARNING

WARNING