Leon Mk1

| Piston and connecting rod: disassembly and assembly |

| 1 - | Piston rings |

| q | Stagger the cuts by 120° |

| q | Remove and install, with the help of pliers for rings |

| q | Carefully remove and install the oil scraper rings made up of three pieces, by hand |

| q | The word “TOP” indicates the piston head |

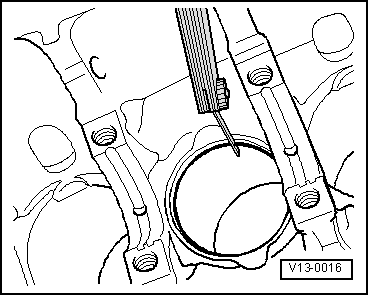

| q | Check the play at the ends of the rings → Fig. |

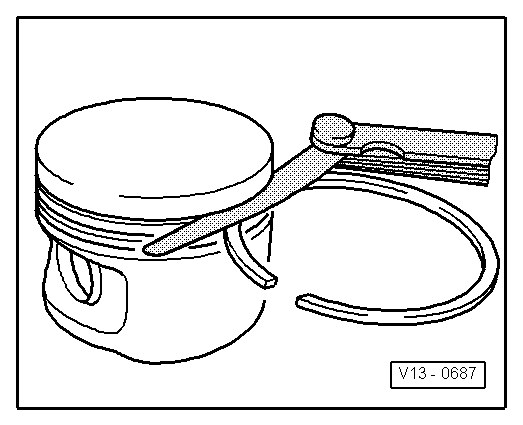

| q | Check the play between piston rings and piston grooves → Fig. |

| 2 - | Piston |

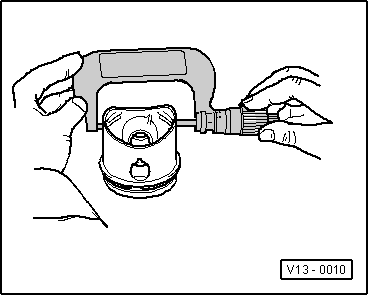

| q | Check → Fig. |

| q | Mark the assembly position and the cylinder to which it belongs. |

| q | The arrow on the piston head should point toward the pulley. |

| q | Assemble with casing to assemble rings. |

| 3 - | Piston pin |

| q | If difficult to move, heat the piston to 60° |

| q | Remove and install with -T20019- |

| 4 - | Securing washer |

| 5 - | Connecting rod |

| q | Renew unit only |

| q | Mark the position on cylinder -A- |

| q | Assembly position: the marks -B- should point toward the pulley |

| q | Axial guided by piston |

| 6 - | Half bearings |

| q | Place the half bearings on the block, ensuring they are centred |

| q | Ensure that used half bearings are not used. |

| First measure pre-tension → Fig. |

| q | Measure the radial play with Plastigage: |

| New: 0.020 … 0.061 mm |

| Wear limit: 0.091 mm |

| When measuring the radial play do not turn the crankshaft. |

| 7 - | Engine block |

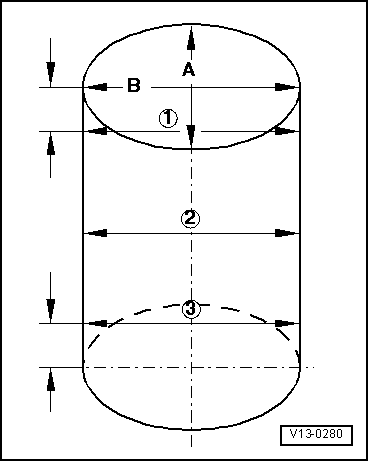

| q | Check the bore of the cylinders → Fig. |

| q | Pistons and cylinder dimensions → Chapter |

| 8 - | Connecting rod caps |

| q | Check the assembly position |

| q | If the connecting rods are cracked, the cap can only be placed in one position, and only on a given connecting rod |

| 9 - | Connecting rod bolt |

| M7: 20 Nm + 1/4 turn (90°) |

| M8: 30 Nm + 1/4 turn (90°) |

| q | Renew |

| q | Apply lubricant to the threads and contact surface |

| q | To measure the radial play, tighten to 20 or 30 Nm, without retightening. |

| Piston ring | Wear limit | |

| Ring compression | 1.0 mm | |

| Oil scraper rings | 1 piece 3 pieces | 1.0 mm _ → Note |

| 1) | It is not possible to make an indication as to the wear limit. |

|

|

| Piston ring | Wear limit | |

| Ring compression | 0.15 mm | |

| Oil scraper rings | 1 piece 3 pieces | 0.15 mm not measured |

|

|

Note!

Note!

|

|

|

|

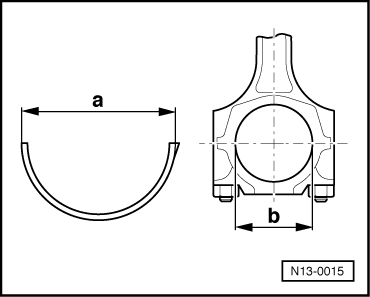

| dimension -a- of the half bearing | |

| - | diameter of the connecting rod -b- |

| = | pre-tension |

|