| –

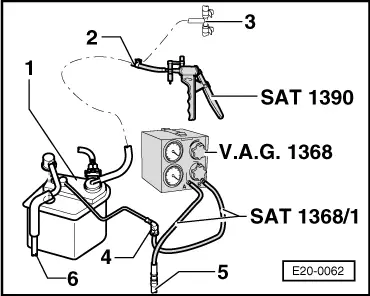

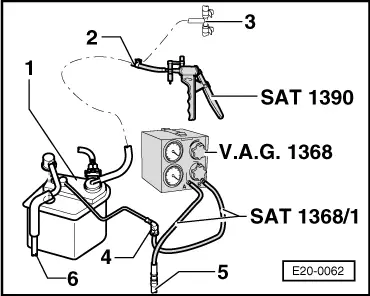

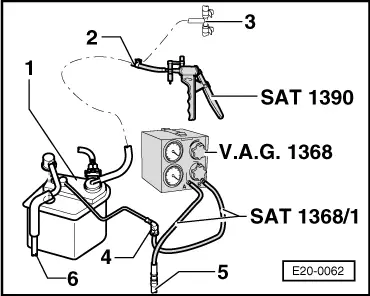

| Pull breather pipe -2- off activated charcoal filter canister -1- at T-piece -3-. |

| –

| Connect hand vacuum pump -SAT 1390- to pipe -2-. |

| –

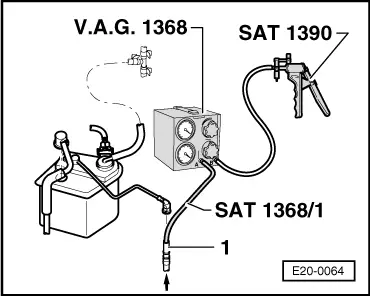

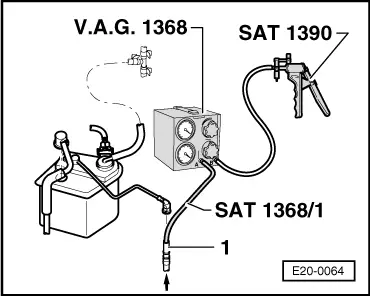

| Pull breather pipe -5- to activated charcoal filter canister off fuel tank and connect to vacuum tester -V.A.G 1368- -connection A-. Use adapter -SAT 1368/1-. |

| –

| Connect vacuum tester -V.A.G 1368- -connection B- to breather pipe -4- to activated charcoal filter canister. Use adapter -SAT 1368/1-. |

| –

| Set vacuum tester to position -B-. |

| –

| Operate hand vacuum pump -SAT 1390- several times. A vacuum must not build up. |

| –

| Check breather connection -6- on activated charcoal filter canister -1- for soiling, clean if necessary. |

| If vacuum does not build up: |

| –

| Remove fuel filler cap. |

|

|

|

Note!

Note!

Note!

Note!