| –

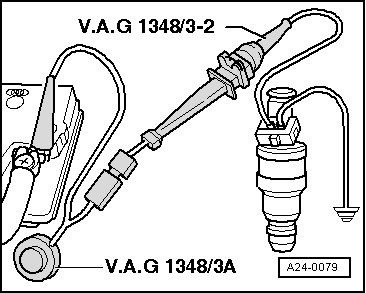

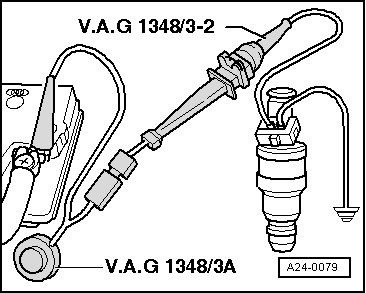

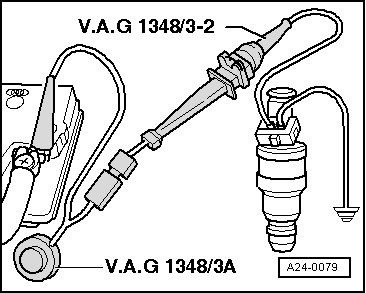

| Connect one contact of the injector to be tested to engine earth using auxiliary cables from -V.A.G 1594C-. |

| –

| Connect the second injector contact with auxiliary cable to remote control -V.A.G 1348/3- using adapter cable -V.A.G 1348/3-2-. |

| –

| Connect crocodile clip to battery (+). |

| –

| Operate remote control -V.A.G 1348/3- for 30 seconds. |

| –

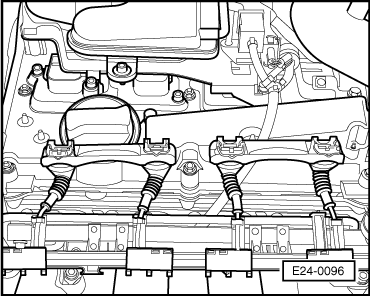

| Repeat check on the other injectors. To do this use new measuring beakers. |

| –

| After all injectors have been activated, place the measuring glasses on a horizontal surface and compare the injected quantity. Specification: 133...157 ml per injector |

| If the measured values of one or more injectors are above or below the prescribed specifications: |

| –

| Renew defective injector. |

| Perform installation of injectors in reverse order. When doing this note the following: |

| t

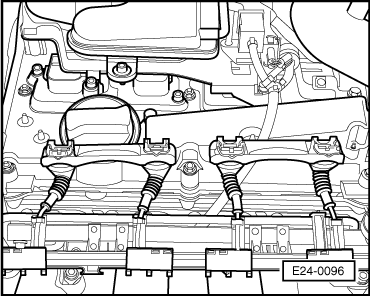

| Renew O-rings on all injectors and lightly moisten with clean engine oil. |

| t

| Insert injectors vertically and in the correct position into the fuel rail and secure with retaining clips. |

| t

| Fit fuel rail with secured injectors onto intake manifold and press in evenly. |

|

|

|

Note!

Note! Note!

Note! Note!

Note!

Note!

Note! Note!

Note! Note!

Note!