Leon Mk1

| Dismantling and assembling pistons and conrods |

| 1 - | Circlip |

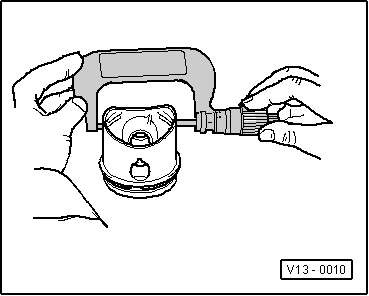

| 2 - | Piston pin |

| q | If difficult to remove, heat piston to 60°C |

| q | Remove and install with drift -T20019- |

| 3 - | Piston |

| q | Checking → Fig. |

| q | Mark installation position and cylinder number |

| q | Arrow on piston crown points to pulley end |

| q | Install using piston ring clamp |

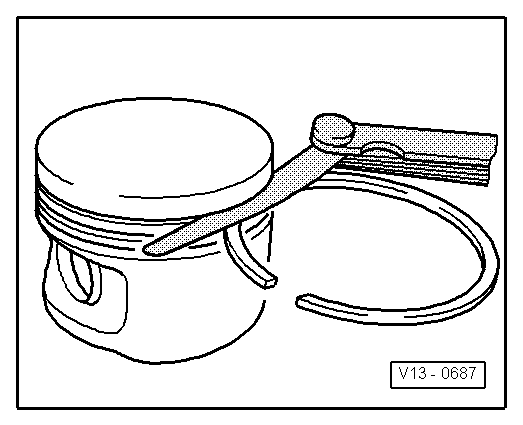

| 4 - | Compression rings |

| q | Offset gaps by 120° |

| q | Remove and install compression rings with piston ring pliers |

| q | “TOP” faces towards piston crown |

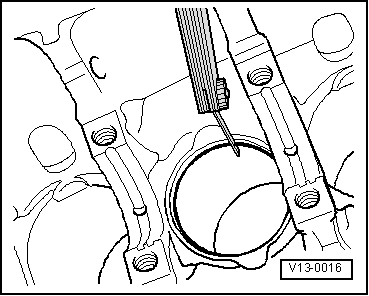

| q | Checking ring gap → Fig. |

| q | Checking ring to groove clearance → Fig. |

| 5 - | Oil scraper ring |

| q | Remove and install 2-part oil scraper rings carefully by hand |

| q | “TOP” faces towards piston crown |

| q | Checking ring gap → Fig. |

| q | Checking ring to groove clearance → Fig. |

| 6 - | Conrod |

| q | Only renew as a set |

| q | Mark cylinder number -A- |

| q | Installation position: Marking -B- faces towards pulley end |

| q | Guided axially via piston |

| 7 - | Conrod bearing cap |

| q | Note installation position |

| q | Link rods split through cracking may only be placed in one position and only with the proper link rod |

| 8 - | Conrod bolt, 20 Nm + 1/4 turn (90°) further |

| q | Renewing |

| q | Oil threads and contact surface |

| q | To measure radial clearance tighten to 20 Nm but not further |

| q | The turning further can be done in several stages |

| q | The turning further angle can be measured with protractor -T20030- |

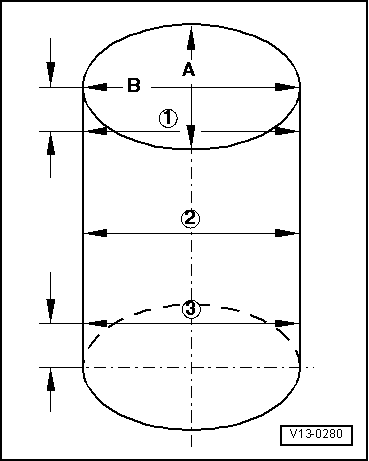

| 9 - | Aluminium cylinder block |

| q | Checking cylinder bores → Fig. |

| q | Piston and cylinder dimensions → Chapter |

| 10 - | Bearing shell |

| q | Do not interchange used bearing shells |

| q | Insert bearing shells in the centre |

| q | Check radial clearance with Plastigage: New: 0.020...0.061 mm Wear limit: 0.091 mm Do not rotate crankshaft when checking radial clearance |

|

|

| Piston segment | Wear limit | |

| for compression | 1.0 mm | |

| oil scraper | 1.0 mm | |

|

|

| Piston segment | Wear limit | |

| Kompressionsring | 0.15 | |

| Ölabstreifring | 0.15 | |

|

|

Note!

Note!

|

|