| –

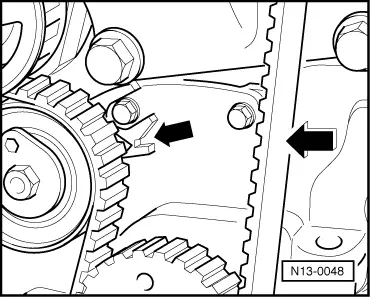

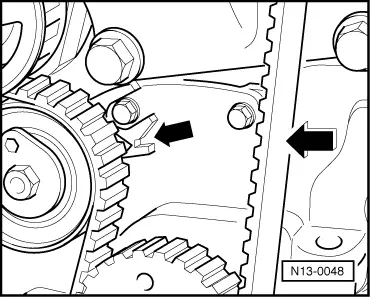

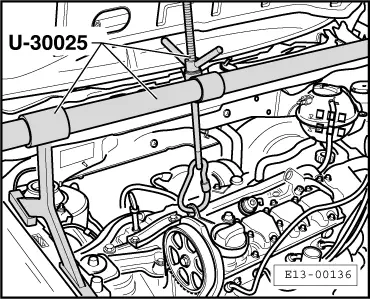

| Note the position of the tensioning roller indicator -arrow-. Press the toothed belt with firm thumb pressure. The indicator must move. |

| –

| Release tension on toothed belt. |

| –

| Turn crankshaft two turns in engine direction of rotation. |

| –

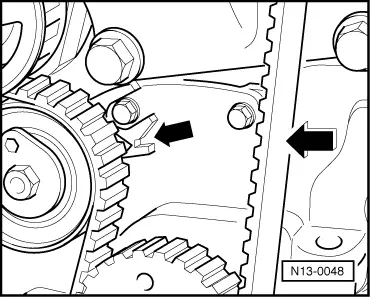

| Then check the position of the indicator. It must have returned to its original position. |

| If tensioning roller does not return to initial position: |

| –

| Replace tensioning roller. |

| If the tensioning roller is OK: |

| –

| Reinstall belt pulley and toothed belt guard upper and lower parts. |

| –

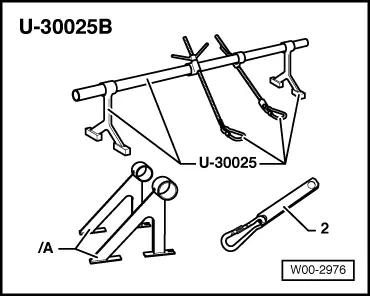

| Refit right engine mounting with new bolts → Chapter, Engine assembly mounting. |

| –

| Refit the ribbed belt and the cover. |

Note! | When installing the ribbed belt ensure that it sits correctly in the pulleys. |

| The rest of the assembly is basically a reverse of the dismantling sequence. |

|

|

|

Note!

Note!

Note!

Note!