| –

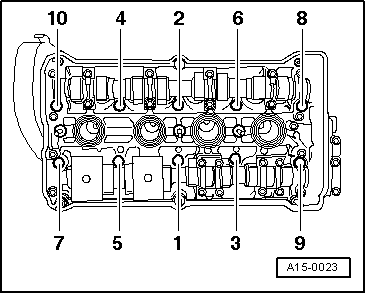

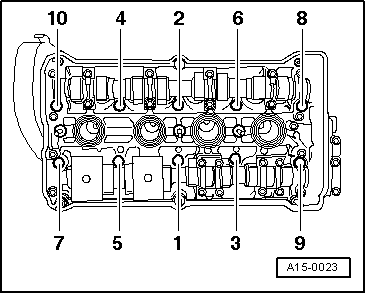

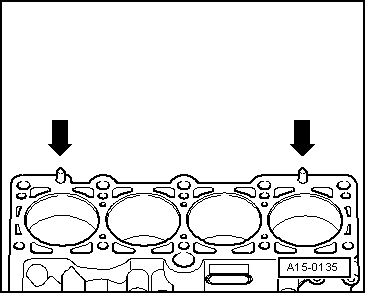

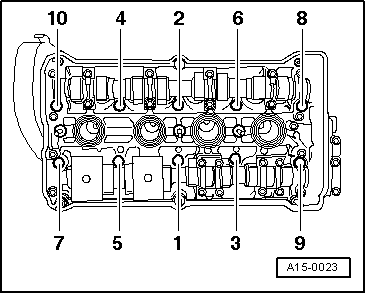

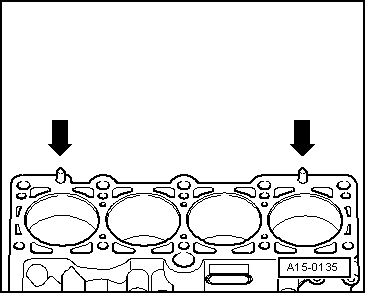

| Tighten cylinder head bolts in tightening sequence as follows: |

| –

| First tighten all bolts to 40 Nm. |

| –

| Then retighten all bolts 1/4 turn (90°) further using a rigid wrench. |

| –

| Then retighten all bolts again 1/4 turn (90°). |

Note | It is not necessary to retighten cylinder head bolts after repairs. |

| –

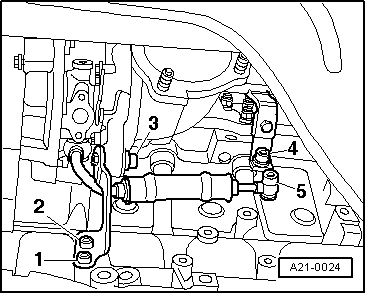

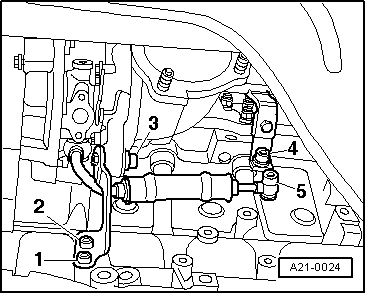

| Replace the turbocharger/exhaust manifold gasket, and firmly screw the turbocharger, together with its mounting, to the cylinder block. |

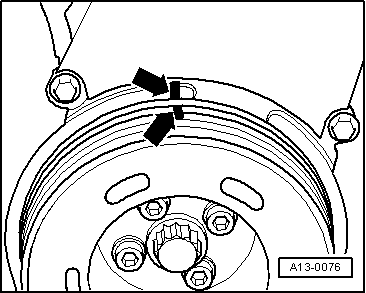

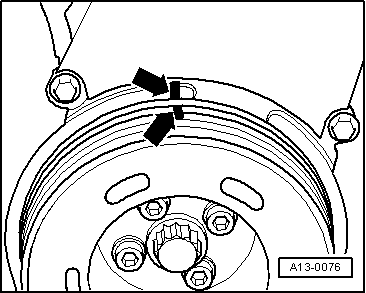

| Installing timing belt and adjusting valve timing → Chapter. |

| Continue installation following reverse order for removing. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note