Leon Mk1

| Part II |

| 1 - | Seal bolt 40 Nm |

| 2 - | Ring gasket |

| q | In case of leakage, cut out and replace sealing ring |

| 3 - | Spring |

| q | For pressure relief valve approx. 4 bar |

| 4 - | Piston |

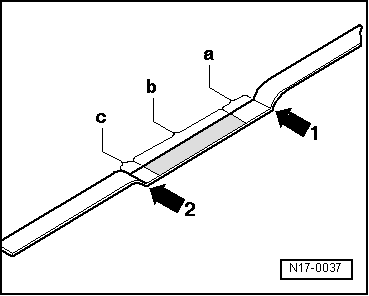

| q | For pressure relief valve approx. 4 bar |

| 5 - | Gasket |

| q | Replace |

| 6 - | Return locking valve, 8 Nm |

| 7 - | O-ring |

| q | Replace |

| q | Slip on as far as collar of pipe → Item |

| 8 - | Wiring |

| 9 - | Securing clip |

| q | Check for firm attachment |

| 10 - | Seal bolt 15 Nm |

| 11 - | Ring gasket |

| q | In case of leakage, cut out and replace sealing ring |

| 12 - | 20 Nm |

| 13 - | Oil supply pipe |

| q | To the turbocharger |

| 14 - | Union screw, 30 Nm |

| 15 - | Gasket |

| q | Replace |

| 16 - | Oil pressure switch -F1-, 1.4 bar |

| q | 25 Nm |

| q | Black |

| q | Testing → Chapter |

| 17 - | Ring gasket |

| q | In case of leakage, cut out and replace sealing ring |

| 18 - | 15 Nm + 1/4 turn (90°) |

| q | Replace |

| 19 - | Oring seal |

| q | Replace |

| q | Secure with lugs onto oil cooler |

| 20 - | Oil filter |

| q | Loosen with the rotation tool -U-40078- |

| q | Tighten by hand |

| q | Observe the installation instructions printed on the filter |

| 21 - | 25 Nm |

| 22 - | Oil cooler |

| q | Check that there is sufficient clearance with the adjacent parts |

| q | See note → Chapter |

| q | Lubricate the contact surfaces with the oil filter mounting outside the seal with lubricant → Parts Catalogue |

| 23 - | Oil filter bracket |

| q | With pressure relief valve approx. 4 bar |