| –

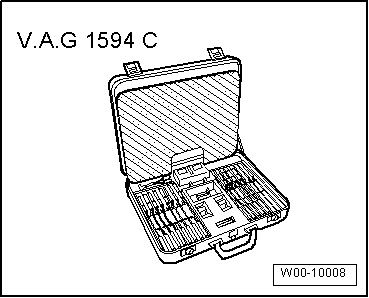

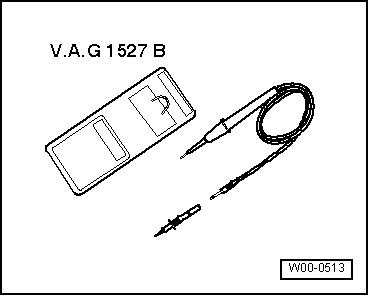

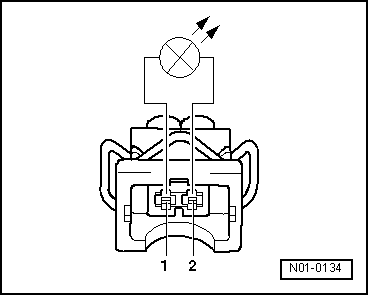

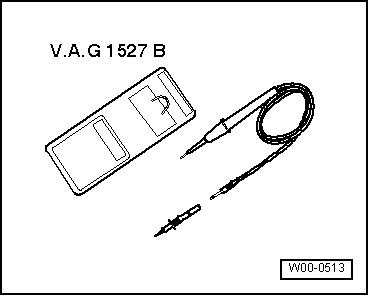

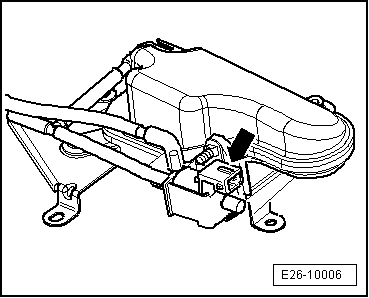

| Connect voltage tester -VAG 1527B- with measuring tool set -VAG 1594C- to disconnected terminal connector of. |

| –

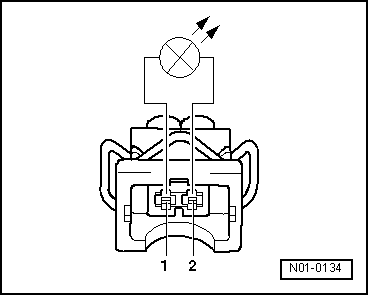

| Start engine and run at idling speed. The LED must light. |

| If LED lights (voltage supply OK): |

| –

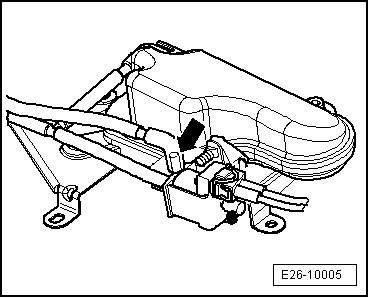

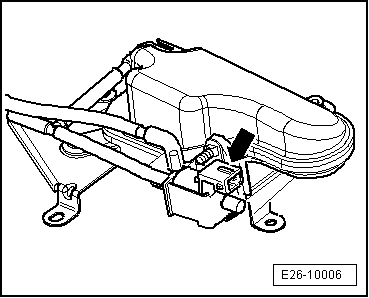

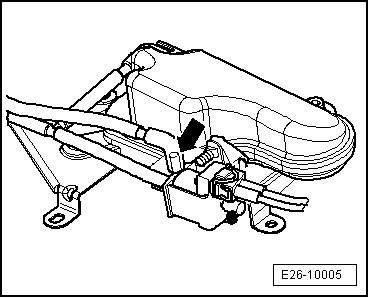

| Replace the Secondary air inlet valve -N112-. |

| –

| Plug in a 2-pin connector. |

|

|

|