Leon Mk1

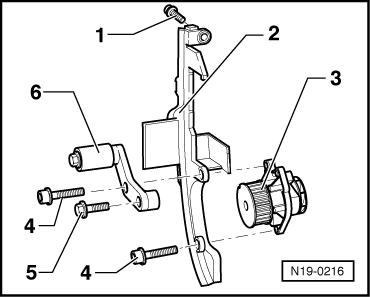

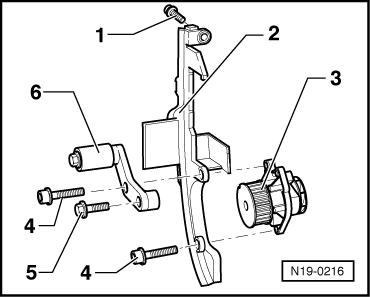

| Coolant pump removal and installation |

| Special tools and workshop equipment required |

| t | tester for anti-freeze protection -T10007- |

| t | pliers for spring-type clips -T20029- |

| t | counter support -T20018A- |

| t | torque wrench -SAT 8010- |

| t | drip tray -V.A.G 1306- |

Note!

Note!

|

|

|

|

|