| –

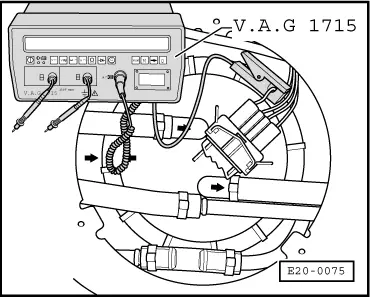

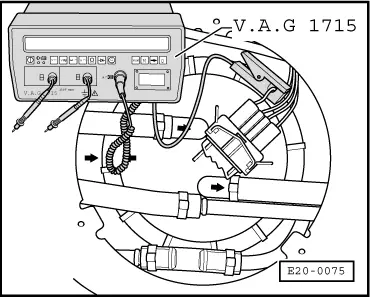

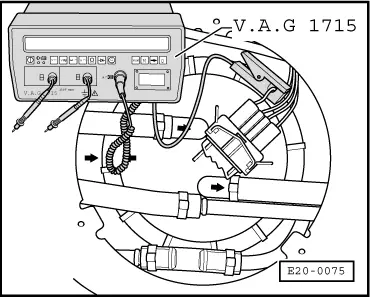

| By means of a current clamp, connect multimeter -V.A.G 1715- to one of the fuel pump supply cables (external contacts of the flange connector). |

| –

| Start the engine and run at idling speed. |

| –

| Measure the current draw of the fuel pump. |

|

| Specifications: max. 8 amps. |

Note! | If the fuel system malfunction is intermittent, you can perform the check during a test drive with the help of a 2nd person. |

| Observe safety precuations when test driving → Chapter. |

| If the current draw is exceeded: |

| –

| Fuel pump defective, renew fuel delivery unit → Chapter, Fuel delivery unit: removal and installation. |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!