Leon Mk1

| Engine support: Installing and removing (Ibiza) |

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

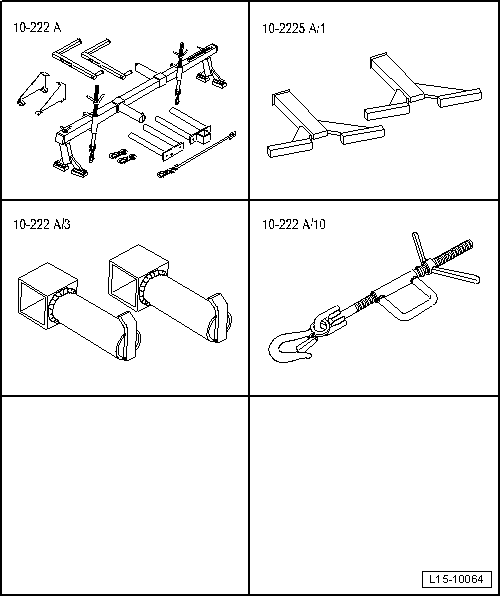

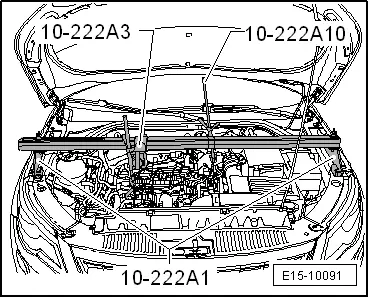

| Special tools and workshop equipment required |

| t | Socket -10 222A-, see equivalent → Anchor |

| t | Adapter -10 222A/1-, see equivalent → Anchor |

| t | Adapter -10 222A/3-, see equivalent → Anchor |

| t | Adapter -10 222A/10-, see equivalent → Anchor |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

WARNING

WARNING Caution

Caution