| –

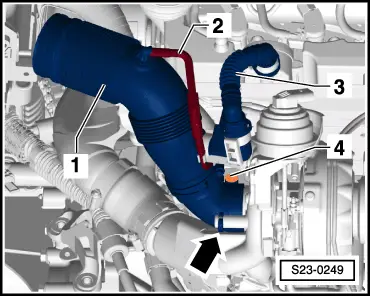

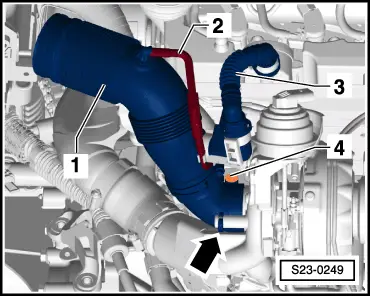

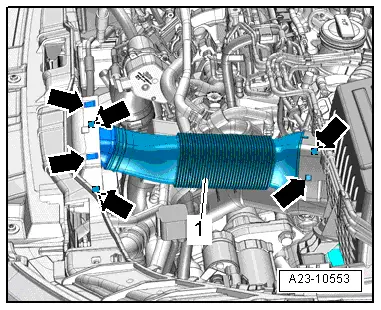

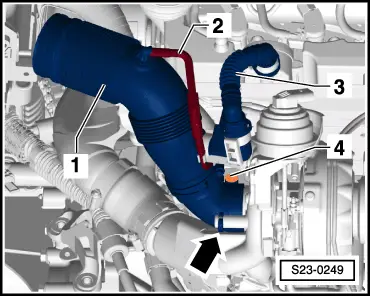

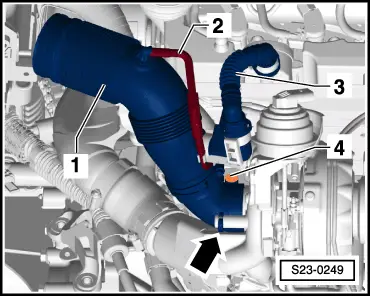

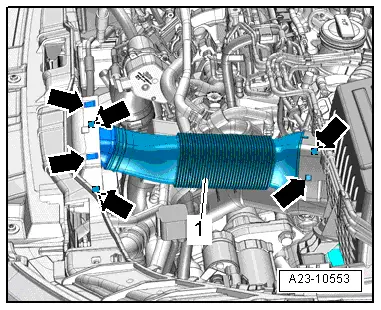

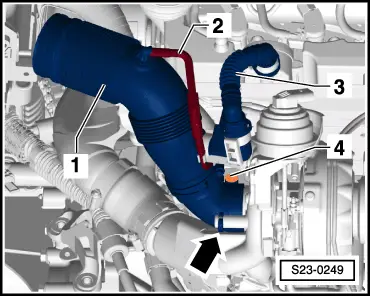

| When mounting intake connecting pipe on turbocharger, it must be ensured that intake connecting pipe is correctly seated on the bolt of the turbocharger. -arrow-. |

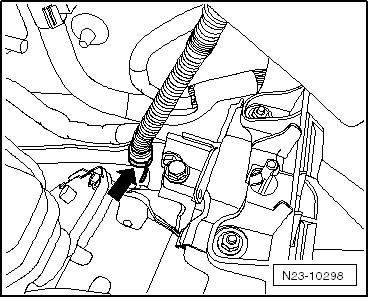

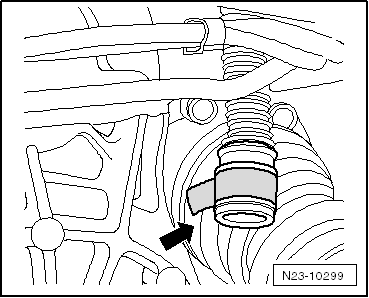

| Installation is carried out in reverse order, noting the following: |

Note | t

| If the air filter element is very dirty or wet, dirt or water could reach the air mass meter -G70- and affect the air mass value. This would lead to loss of power, since a smaller injection quantity is calculated. |

| t

| In order to avoid functional problems, you should cover the critical air-conducting components such as air mass meter, air pipes etc. with a clean cloth when blowing out the air filter housing with compressed air. |

| t

| Hose connections and air pipes and hoses must be free from oil and grease before fitting. |

| t

| Use a silicone-free lubricant when installing the air hoses. |

| –

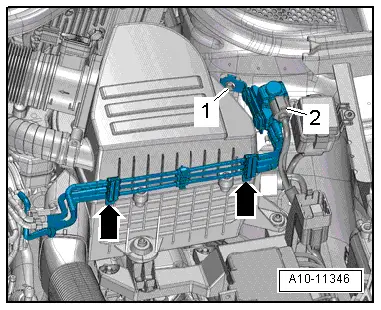

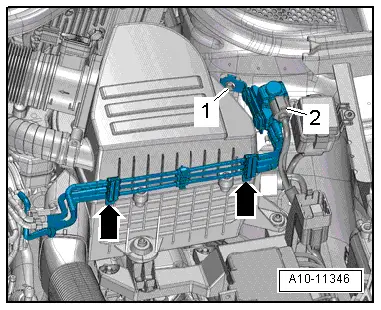

| Check suction hose (engine intake side) for salt residue, dirt and leaves and, if necessary, clean. |

| –

| Check air duct leading from lock carrier to air filter housing for dirt and leaves. Clean if necessary. |

| Remaining assembly is performed in reverse sequence. |

|

|

|

Note

Note

Note

Note