WARNING | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

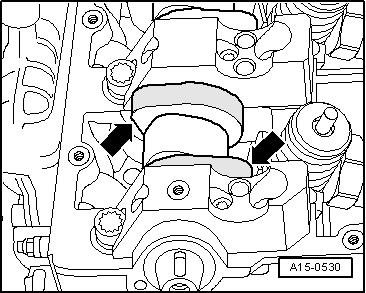

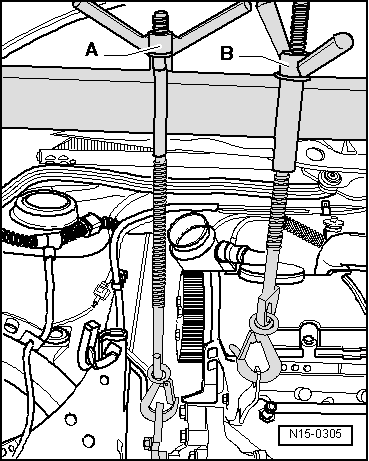

| Route all the various lines (e.g. for fuel, hydraulics, activated charcoal filter system, coolant and refrigerant, brake fluid and vacuum) and electrical wiring in their original positions. |

| t

| Ensure that there is sufficient clearance to all moving or hot components. |

|

Note | t

| Always renew cylinder head bolts. |

| t

| If repairing, carefully remove any remaining gasket material from the cylinder block and cylinder head. Ensure that no long scores or scratches are made on the surfaces. When using abrasive paper do not use a grade less than 100. |

| t

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle gasket very carefully. Damage to the silicone layer or the indented area will lead to leaks. |

| t

| Carefully remove remains of emery and abrasives. |

| –

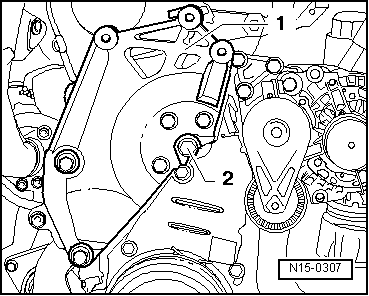

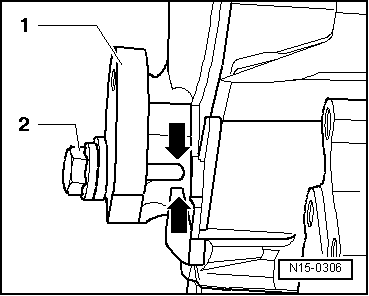

| Turn crankshaft to TDC marking before fitting cylinder head. |

| –

| Turn crankshaft against engine direction of rotation until all pistons are about the same distance below TDC. |

| –

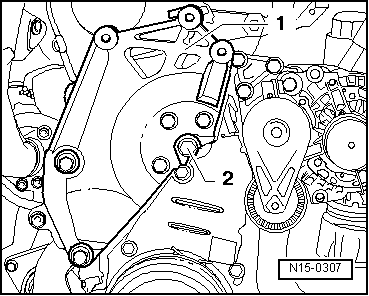

| Position cylinder head gasket. |

| –

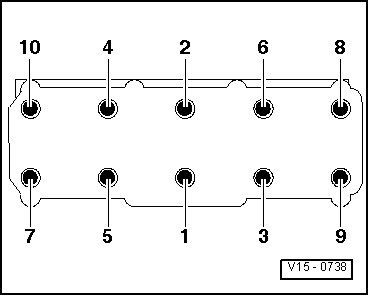

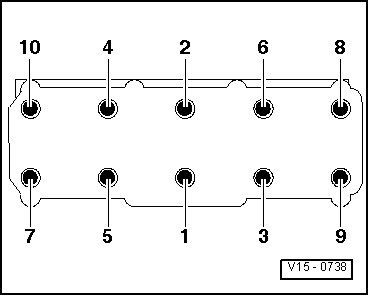

| Fit cylinder head and hand tighten all 10 cylinder head bolts. |

|

|

|

Note

Note

Note

Note