Leon Mk1

| Assembly overview - valve gear |

| 1 - | 20 Nm + 1/4 turn (90°) further |

| q | Renew. |

| q | Observe sequence when loosening and tightening → Chapter. |

| 2 - | Rocker arm shaft |

| q | Do not interchange. |

| 3 - | Cylinder head bolt |

| q | Observe sequence when loosening and tightening → Chapter. |

| q | Before installing, insert washers ( → Item) in cylinder head. |

| 4 - | Washer |

| q | For cylinder head bolts. |

| q | Insert in cylinder head before installing bearing caps |

| 5 - | Bucket tappet |

| q | Do not interchange. |

| q | With hydraulic valve clearance compensation. |

| q | Place down with contact surface facing downwards |

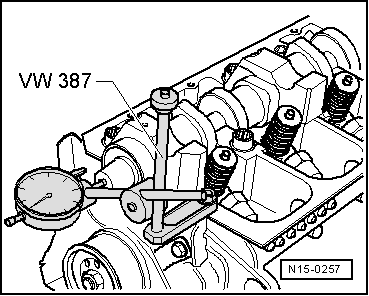

| q | Before installing, check camshaft axial clearance → Fig.. |

| q | Oil contact surface. |

| q | Before removing, remove camshaft bearing caps. |

| 6 - | Valve cotter |

| 7 - | Valve spring plate |

| 8 - | Outer valve spring |

| q | Removing and installing → Chapter. |

| q | With valve spring compressor -2037-, with cylinder head removed |

| 9 - | Inner valve spring |

| q | Removing and installing → Chapter. |

| q | With valve spring compressor -2037-, with cylinder head removed |

| 10 - | Valve stem seal |

| q | Renewing → Chapter. |

| 11 - | Valve guide |

| q | Checking → Chapter. |

| 12 - | Unit injector |

| q | Removing and installing → Chapter. |

| 13 - | Cylinder head |

| q | See note → Chapter. |

| 14 - | Seal |

| q | Do not additionally oil or grease the oil seal sealing lip. |

| q | Before installing, remove residual oil from camshaft journal using a clean cloth. |

| q | To install, mask off groove on camshaft taper (e.g. using Sellotape) |

| q | Removing and installing → Chapter. |

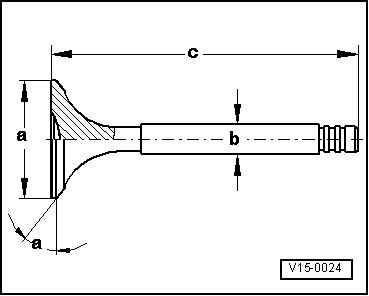

| 15 - | Valves |

| q | Valve dimensions → Fig.. |

| 16 - | Bearing shell |

| q | Do not interchange used bearing shells (mark). |

| q | Ensure that retaining lugs are correctly seated in bearing caps and cylinder head |

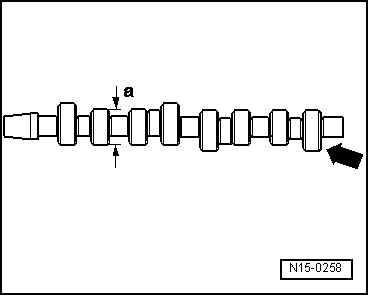

| 17 - | Camshaft |

| q | Checking axial clearance → Fig.. |

| q | Removing and installing → Chapter. |

| q | Check radial clearance with Plastigage, wear limit: 0.11 mm. |

| q | Runout: max. 0.01 mm. |

| q | Identification → Fig.. |

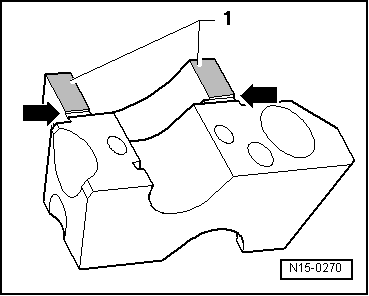

| 18 - | Bearing cap |

| q | Installation sequence → Chapter |

| q | To install, seal parting surfaces of bearing caps 1 and 5 with sealant -AMV 174 004 01- → Fig. |

| 19 - | 8 Nm + 1/4 turn (90°) further |

| q | Renew. |

Note

Note

|

|

Note

Note

|

|

| Dimension | Inlet valve | Exhaust valve | |

| Ø a | mm | 35.95 | 31.45 |

| Ø b | mm | 6.980 | 6.956 |

| c | mm | 89.95 | 89.95 |

| α | ∠° | 45 | 45 |

|

|