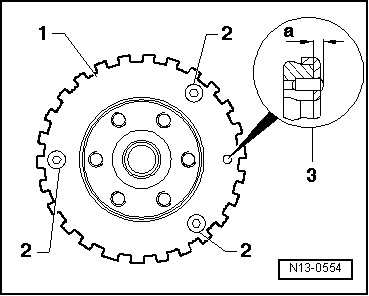

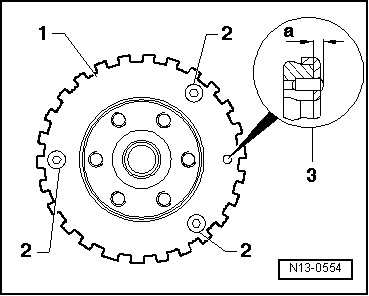

| Removing and installing sender wheel |

| –

| Renew sender wheel -2- each time bolts -1- are loosened. Specified torque: 10 Nm + 90° (1/4 turn) |

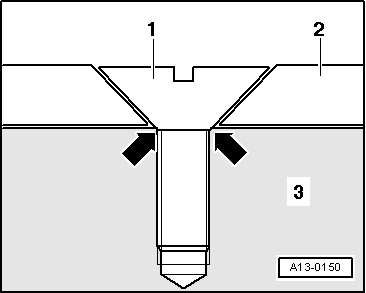

Note | The second time the bolts are tightened, the contact points in the sender wheel for the countersunk heads are deformed so far that the bolt heads seat on the crankshaft -3-, -arrows- and the sender wheel is loose under the bolts. |

|

|

|