| –

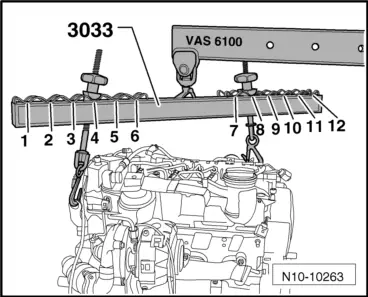

| Hook the support tool -3033- on the engine and on the workshop crane -VAS 6100-, as shown in the figure. |

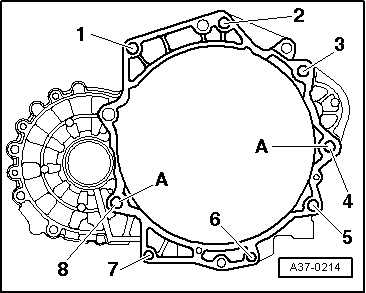

| Vibration damper side: item 8. |

| Installation is carried out in the reverse order of removing, when doing this note the following. |

Note | t

| When fitting, replace the self-locking nuts and bolts. |

| t

| Renew bolts which have a specified tightening angle, as well as seals and gaskets. |

| t

| Secure all hose connections with the correct hose clips (same as original equipment) → Parts catalogue. |

| t

| Clean input shaft splines and, for used clutch plates, hub splines; remove corrosion and apply a thin coat of grease → Parts Catalogue to the splines. Then move the clutch plate on the input shaft from side to side, until the hub moves smoothly on the shaft. Excess grease must be removed. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

WARNING

WARNING