Leon Mk1

|

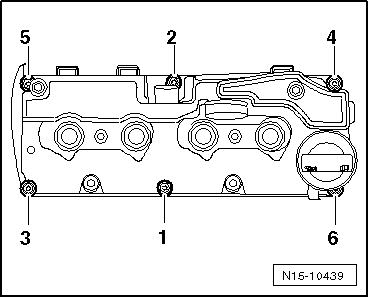

| 1 - | Seal |

| q | Renew if damaged or leaking. |

| 2 - | Cylinder head cover |

| q | removing and fitting → Chapter |

| 3 - | O ring |

| q | Replace |

| 4 - | Flexible hose |

| q | For crankcase ventilation. |

| q | Press release buttons to remove. |

| 5 - | Sealing bush |

| q | For fuel rail |

| q | If this is damaged, replace it |

| 6 - | Retainer |

| q | For electrical wiring |

| 7 - | Grommet |

| 8 - | Clamping piece |

| 9 - | 8 Nm |

| 10 - | Fuel rail |

| q | removing and fitting → Chapter |

| q | Observe rules for cleanliness → Chapter. |

| q | Do not attempt to bend high-pressure pipes to a different shape |

| q | Installing high-pressure pipes → Chapter |

| 11 - | Bolt, 22 Nm |

| 12 - | 8 Nm + 180° (1/2 turn further) |

| q | Replace |

| 13 - | Fuel return line |

| 14 - | O ring |

| q | Replace |

| 15 - | Injector (piezo injectors) |

| q | The following components and seals or O-rings must be replaced after each gearbox renewal: „Screws of the clamping piece“„Copper washer“„O-ring in the adapter shaft of the injector valve“„O-ring from the injector valve return connection“ |

| q | The following components and seals or O-rings must always be replaced when an injector valve is renewed: „Clamping piece “„Screws of the clamping piece“„Copper washer“„O-ring in the adapter shaft of the injector valve“„O-ring from the injector valve return connection“. |

| q | When re-installing „high-pressure injector pipe“ check taper seats visually for damage, scores and corrosion (always renew if damaged) |

| q | If they are to be re-installed, the injectors, high-pressure pipes and clamping pieces must always be re-fitted in their original positions (cylinder). |

| q | removing and fitting → Chapter |

| 16 - | O ring |

| q | Replace |

| 17 - | Copper washer |

| 18 - | Seal |

| q | removing and fitting → Chapter |

| q | In rocker finger cover |

| 19 - | Filler cap |

| 20 - | Seal |

| 21 - | Seal |

| 22 - | Retainer |

| q | For electrical wiring |

| 23 - | 9 Nm |

| q | Observe tightening sequence → Fig.. |

|

|

Caution

Caution