| –

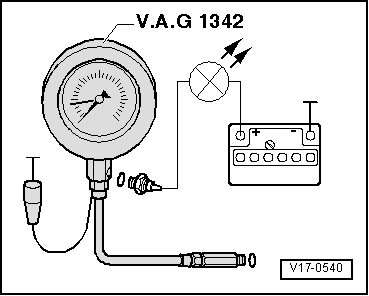

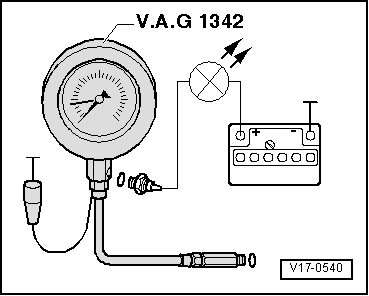

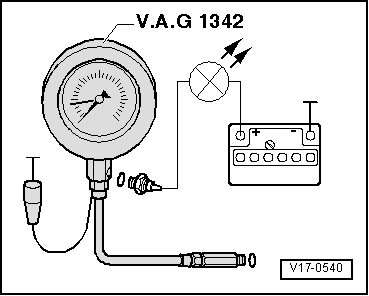

| Remove 0.7 bar oil pressure switch -F1- -brown insulation- and screw into tester. |

| –

| Screw tester into oil filter bracket in place of the oil pressure switch. |

| –

| Connect brown wire of tester to earth (-). |

| –

| Connect diode test lamp -V.A.G 1527 B- to battery positive (+) and oil pressure switch using cables from auxiliary test set -V.A.G 1594/A-. LED must not light up. |

| –

| Start engine and increase speed slowly. The LED must light up at 0.55...0.85 bar, otherwise renew oil pressure switch. |

Note | Observe tester and LED while starting, as switching point of oil pressure switch may already be exceeded when starting. |

| –

| Increase engine speed further. At 2000 rpm and an oil temperature of 80 °C the oil pressure should be at least 2.0 bar. |

| At higher engine speed, oil pressure must not exceed 7.0 bar. If necessary renew oil filter bracket. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note