Leon Mk1

| Assembly overview - oil pump, sump, balancer shaft module |

| 1 - | Balancer shaft assembly |

| q | Remove balancer shaft module → Chapter |

| q | Install balancer shaft module → Chapter |

| q | Before installing, check that the two dowel sleeves for centring balancer shaft module on cylinder block are fitted. |

| 2 - | M7 = 13 Nm + 90° (1/4 turn) further; M8 = 20 Nm + 90° (1/4 turn) further |

| q | Renew |

| q | Observe tightening sequence → Chapter |

| 3 - | Oil extraction pipe |

| 4 - | 10 Nm |

| 5 - | 15 Nm |

| q | Loosen and tighten with T-bar and socket, 10 mm -3185- |

| q | Remove using hexagon key extension, 5 mm -3249-. |

| 6 - | Sump |

| q | Clean sealing surface before fitting. |

| q | Install with silicone sealant -D 176 404 A2-. |

| q | Removing and installing → Chapter. |

| 7 - | 20 Nm |

| 8 - | Bracket |

| q | For charge air pipe between exhaust turbocharger and charge air cooler |

| 9 - | 10 Nm |

| 10 - | Oil level and oil temperature sender -G266- |

| 11 - | Seal |

| q | Renew |

| q | Oil before installing. |

| 12 - | Oil drain plug, 30 Nm |

| q | Renew plug with attached seal. |

| 13 - | Seal |

| q | Fitted firmly |

| q | If leaking, nip open and replace |

| 14 - | Connector |

| q | Black, 3-pin |

| 15 - | Bracket |

| q | For oil level/temperature sender wiring harness. |

| 16 - | 25 Nm |

| 17 - | 10 Nm |

| 18 - | 10 Nm |

| 19 - | Intake connecting pipe |

| q | Clean strainer if soiled |

| 20 - | 10 Nm |

| 21 - | O-ring |

| q | Renew |

| 22 - | Oil pump |

| q | Removing and installing → Chapter. |

| q | Before installing, check that the two dowel sleeves for centring oil pump on balancer shaft module are fitted. |

| 23 - | Oil pump drive shaft |

| 24 - | Circlip |

| q | Must lie in base of groove. |

| q | Renew damaged or over-tensioned circlip. |

| 25 - | Spur gear for balancer shaft |

| 26 - | 20 Nm + 90° (1/4 turn) further |

| q | Renew |

| 27 - | Hub |

| q | For intermediate gear wheel. |

| q | Renew |

| 28 - | 90 Nm + 90° (1/4 turn) further |

| q | Renew |

| 29 - | Thrust washer |

| q | For intermediate gear wheel. |

| 30 - | Intermediate gear wheel |

| q | Renew |

| q | A coating is applied to the new intermediate gear wheel which sets the correct tooth backlash through wear. |

| q | When intermediate gear wheels are coated to areas around the circumference, a white spot is fitted to ensure correct installation position. |

| q | The intermediate gear wheel without white spot is fully coated around the circumference |

Caution

Caution

|

| q | Installation position: Part number must be visible |

| q | Installing → Chapter. |

| q | Installing → Chapter. |

| 31 - | Thrust washer |

| q | For intermediate gear wheel. |

| q | Renew |

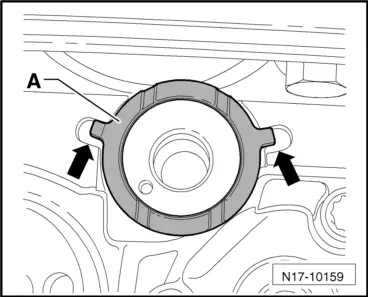

| q | Note installation position → Fig. |

| q | When installing intermediate gear wheel, secure to housing with grease, if necessary |

| 32 - | Crankshaft sprocket |

| 33 - | Dipstick guide |

| q | For oil dipstick. |

| q | Lugs on dipstick and dipstick guide must align. |

| q | Pull out to extract oil. |

| q | The oil level must not be above the max. mark! |

| q | Checking oil level → Chapter |