Leon Mk1

| Removing and installing sump |

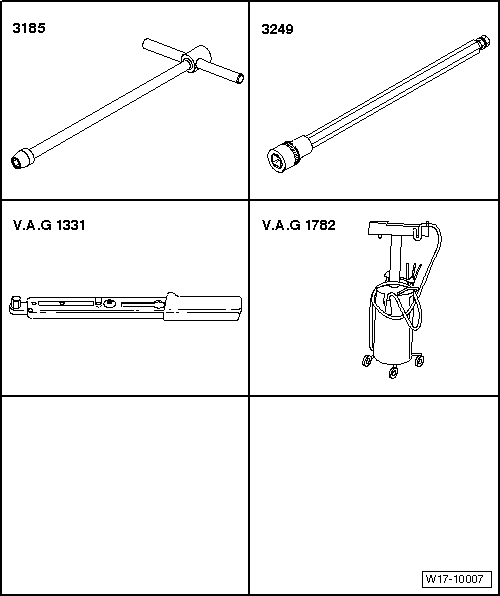

| Special tools and workshop equipment required |

| t | U/J extension and socket, 10 mm -3185- |

| t | Tool insert 5 mm -3249- |

| t | Torque wrench (5...50 Nm) -V.A.G 1331- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

Note

Note

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

WARNING

WARNING