| –

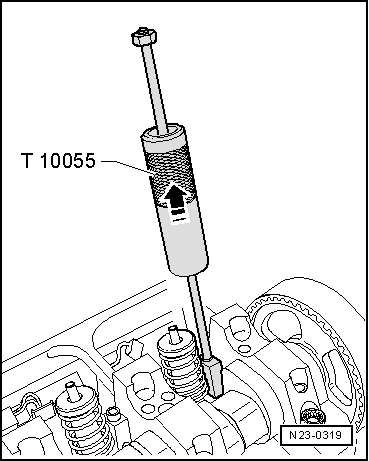

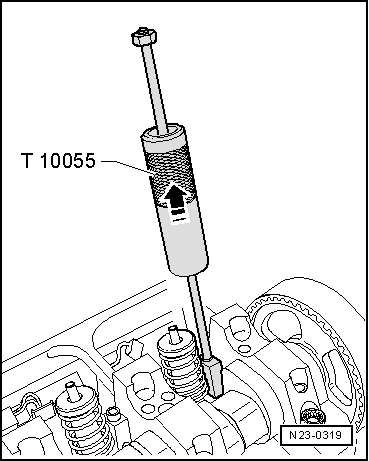

| Seat the puller into the slot on the side of the unit injector instead of the tensioning block. |

| –

| Pull unit injector out of cylinder head seat with gentle taps. |

Note | t

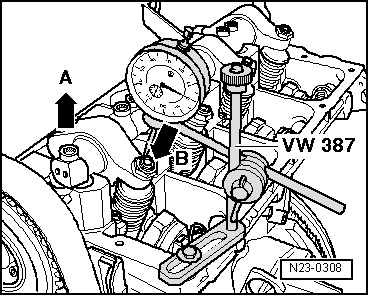

| Each time work is performed which requires adjustment of the unit injector, the adjustment screw in the rocker arm and also the unit injector ball stud must be renewed. |

| t

| New unit injectors are supplied with O-rings and heat shield seal. |

| –

| Heat shield seal and O-rings must be renewed if old unit injector is reused → Chapter. |

| –

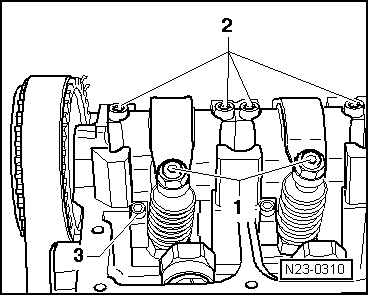

| Before installing unit injector, check that the three O-rings, the heat shield seal and securing clip are seated correctly. |

Note | The O-rings must not be twisted. |

| –

| Oil the O-rings and fit the unit injector into the cylinder head extremely carefully. |

| –

| Push the unit injector evenly into the cylinder head onto its limit stop. |

| –

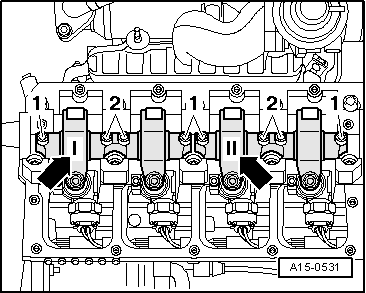

| Insert the clamping block in the slot on the side of the unit injector. |

Note | If the unit injector is not at right angles to the tensioning block the securing bolt may loosen and this can damage the unit injector or the cylinder head. |

| –

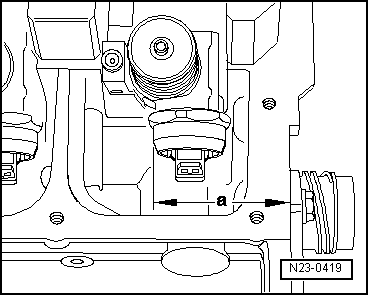

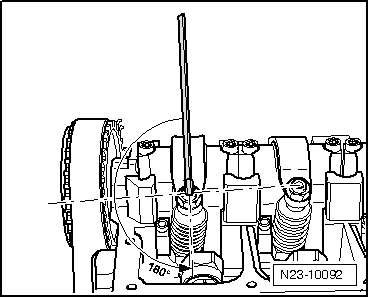

| Therefore align the unit injector as follows. |

| –

| Screw the new securing bolt into the tensioning block only so far that the unit injector can still be turned easily. |

| –

| Now align unit injector at right angles to camshaft mounting brackets. |

|

|

|

Note

Note Note

Note Note

Note