Leon Mk1

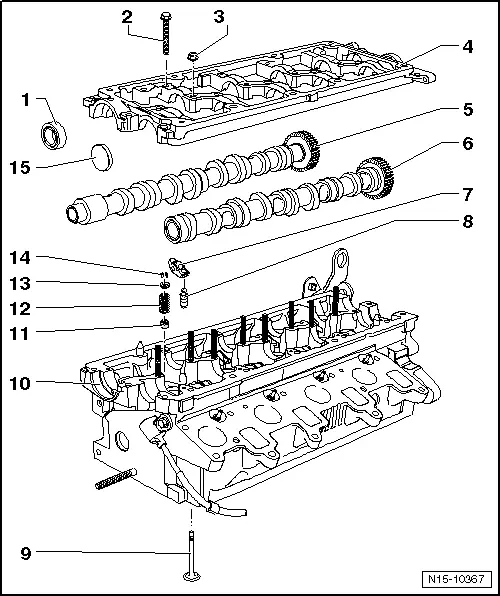

| Valve control: component overview |

| 1 - | Seal |

| q | Do not grease or oil the seal lip of the seal |

| q | Before installing, remove residual oil from camshaft journal using a clean cloth. |

| q | To install, tape over (e.g. using Sellotape) groove in taper of camshaft |

| q | Removing and installing → Chapter. |

| 2 - | 10 Nm |

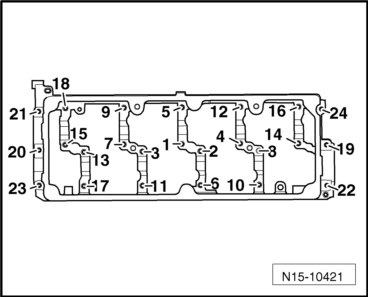

| q | Loosen following the indicated sequence → Fig. |

| q | Note correct sequence when tightening → Fig. |

| 3 - | 10 Nm |

| 4 - | Retaining frame |

| q | With integrated camshaft bearings. |

| q | Loosen following the indicated sequence → Fig. |

| q | Note correct sequence when tightening → Fig. |

| q | Clean sealing surface; machining not permitted |

| 5 - | Exhaust camshaft |

| q | Removing and installing → Chapter. |

| 6 - | Inlet camshaft |

| q | Removing and installing → Chapter. |

| 7 - | Roller rocker finger |

| q | Mark installation position. |

| q | Do not exchange position |

| q | Check roller bearing for ease of movement. |

| q | Oil contact surfaces. |

| 8 - | Hydraulic compensation element |

| q | Mark installation position. |

| q | Lubricate contact surfaces before installing. |

| 9 - | Valve |

| q | Do not rework, only lapping-in is permitted. |

| q | Mark installation position for re-installation. |

| q | Valve dimensions → Chapter. |

| q | Checking valve guides → Chapter. |

| 10 - | Cylinder head |

| 11 - | Valve stem seal |

| q | Removing and installing → Chapter. |

| 12 - | Valve spring |

| 13 - | Valve spring plate |

| 14 - | Cotters |

| 15 - | Cap |

| q | Renew |

|

|