Leon Mk1

| Sealing flange and flywheel |

| 1 - | Seal |

| q | Do not grease or oil the seal lip of the seal. |

| q | Before the installation, clean the remains of oil on the crankshaft journal using a clean cloth. |

| q | Crankshaft oil seal, pulley side: replacement → Chapter |

| 2 - | Sealing flange |

| q | Must sit on dowel sleeves |

| q | Removing and installing → Chapter |

| q | Fit with silicon-based sealant → Spare parts catalogue |

| 3 - | cylinder block |

| q | Removing and installing crankshaft → Chapter. |

| q | Dismantling and assembling pistons and conrods → Chapter |

| 4 - | 60 Nm + 90° (1/4 turn) |

| q | Replace |

| 5 - | Flywheel |

| q | Secure using the counterhold -10 - 201- to loosen the attachment bolts → Anchor |

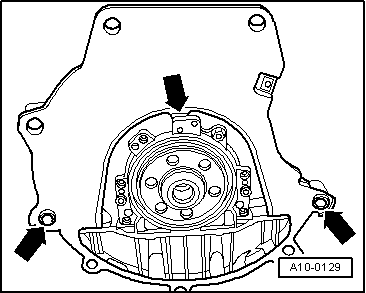

| 6 - | Intermediate plate |

| q | Is suspended on the gasket → Fig. |

| q | Must sit on dowel sleeves |

| q | Do not damage or bend when assembling. |

| 7 - | 15 Nm |

| 8 - | Sealing flange with sealing ring |

| q | Removing and installing → Chapter |

| q | With generator wheel for the engine speed sender |

| q | Always replace completely |

| q | Do not grease or oil the seal lip of the seal. |

| q | Before installing, remove oil residue from crankshaft journal using a clean cloth. |

| q | Use support sleeve supplied when fitting |

| 9 - | Engine speed sender -G28-, 4.5 Nm |

| q | Removing and installing → Chapter |

|

|