Leon Mk1

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

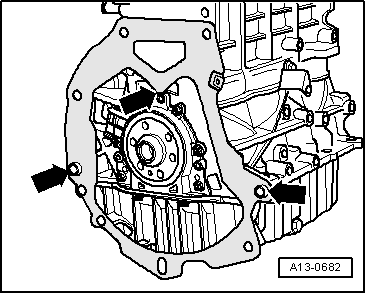

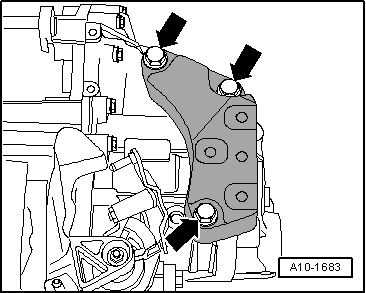

| Item | Bolt | Nm |

| 1 → Remark → Remark, 2 → Remark → Remark | M12×55 | 80 |

| 3 → Remark, 4 → Remark | M12×165 | 80 |

| 5 → Remark | M12×105 | 80 |

| 6 → Remark, 7 → Remark | M10×50 | 40 |

| 8 → Remark | M10×70 | 40 |

|

|

|

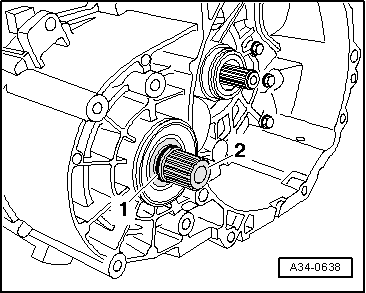

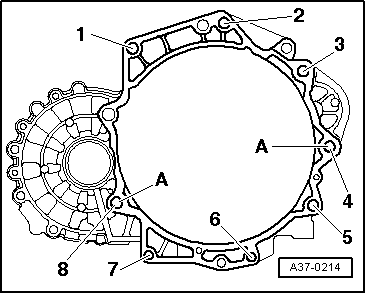

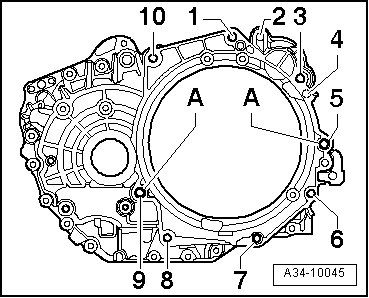

| Item | Bolt | Nm | ||

| 1 1), 3 1), 10 1) | M12x55 | 80 | ||

| 5 1), 9 1) | M12x70 | 80 | ||

| 6 … 8 1) | M10x50 | 40 | ||

| A | Centering handles | |||

| ||||

Note

Note

|

|

|

|

|

Note

Note

|

|

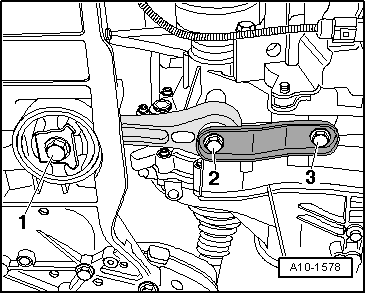

| Component | Nm | |

| Nuts/bolts | M6 | 10 |

| M7 | 15 | |

| M8 | 20 | |

| M10 | 40 | |

| M12 | 65 | |

| Except for the following: | ||

| Direct shift gearbox: Starter motor gearbox | 40 | |

| discrepancies: | ||

| Gearbox support to gearbox. | 60 + 90° → Remark → Remark | |

| Left supercharger air tube to the oil sump | 10 | |

| Pendulum support to gearbox. | 40 + 90° → Remark → Remark | |

| Pendulum support to subframe | 100 + 90° → Remark → Remark | |

| Lock carrier to the bodywork | 10 | |

| Terminal B+ to starter motor | 16 | |

| Earth wire to gearbox | 22 | |

| Front supercharger air tube to the engine block | 22 | |

|

Caution

Caution WARNING

WARNING