| –

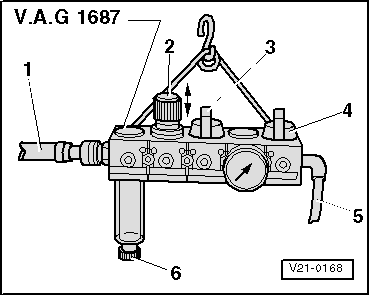

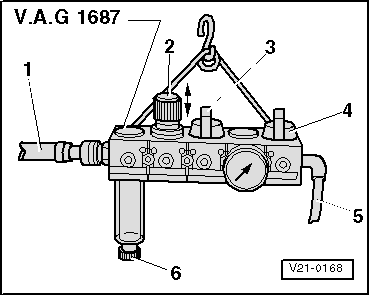

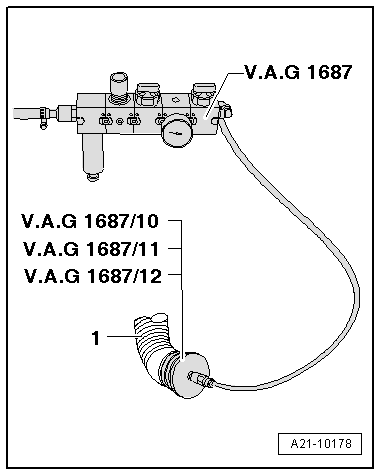

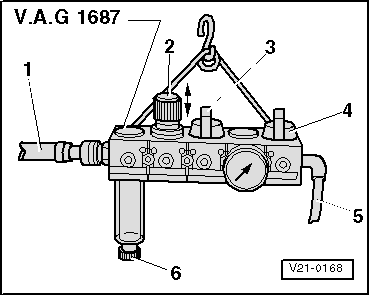

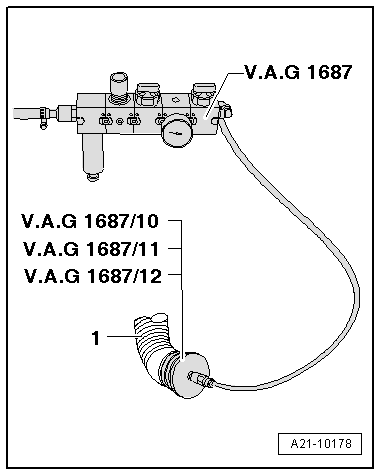

| Unscrew pressure control valve -2- completely and close valves -3- and -4-. |

Note | To turn the pressure regulating valve -2- the knob must be pulled upwards. |

| –

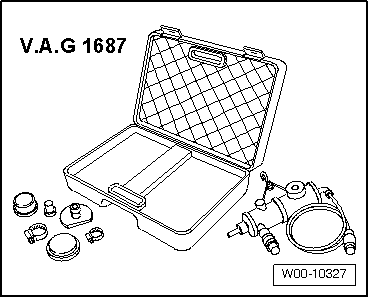

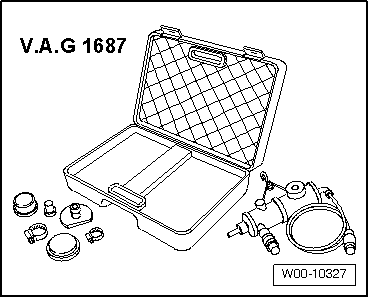

| Connect the cooling system leakage check -VAG 1687- to the compressed air system -1- using a common connecting piece. |

Note | If there is water in sight glass, remove drain plug -6- and drain water. |

Caution | Risk of damage if pressure is set too high. |

| The pressure must not exceed 0.5 bar. |

|

| –

| Adjust pressure to 0.5 bar via pressure control valve -2-. |

| –

| Open valve -4- and wait until test system is pressurised. If necessary, adjust pressure to 0.5 bar again. |

| –

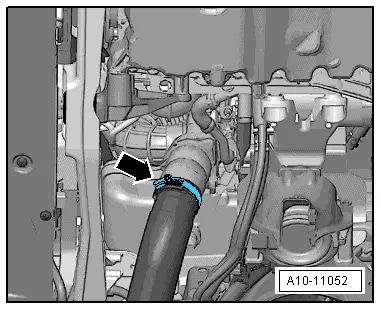

| Check charge air system for audible leaks or leaks that can be felt with the hand; apply commercially available leak detecting spray or use ultrasonic tester -V.A.G 1842-. |

Note | t

| A small amount of air escapes through the valves and enters the engine. Therefore it is not possible to perform a pressure retention test. |

| Installation is carried out in the reverse sequence; note the following: |

Note | t

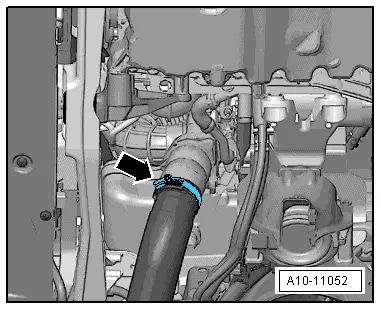

| Release pressure in test circuit by detaching coupling from adapter before removing adapter. |

| t

| Hose connections and air pipes and hoses must be free from oil and grease before fitting. |

|

|

|

Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note