| t

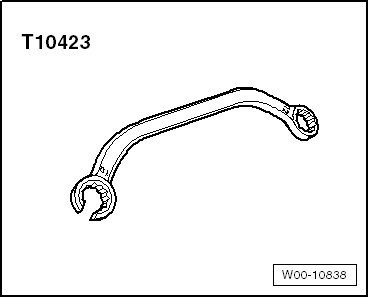

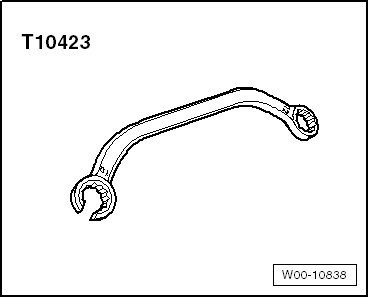

| Ring spanner -T10423-, see equivalent → Anchor |

| t

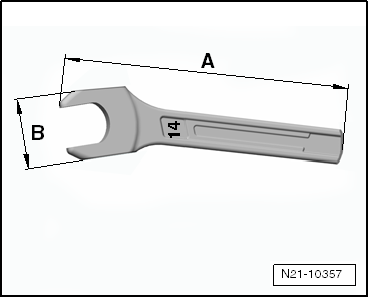

| Special wrench, long reach -T40055- |

| t

| Central diagnosis -VAS 5051B-, see equivalent → Anchor or central diagnosis -VAS 5052-, see equivalent → Anchor |

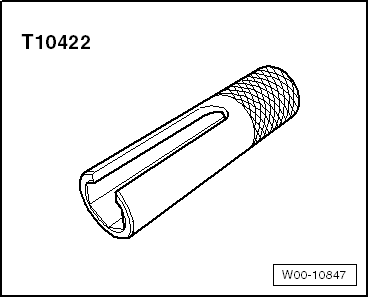

Caution | The specified special tools, especially the socket -T10422-, are only intended to be used for the following work sequences described and should never be used for other screw connections. Deformation may occur when higher tightening torques are applied. |

|

Note | –

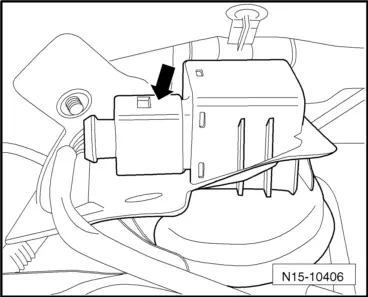

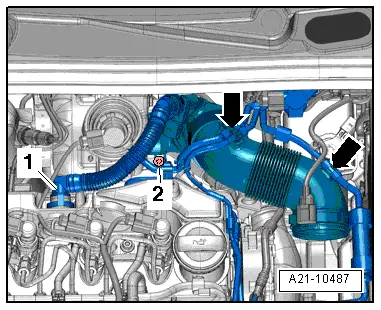

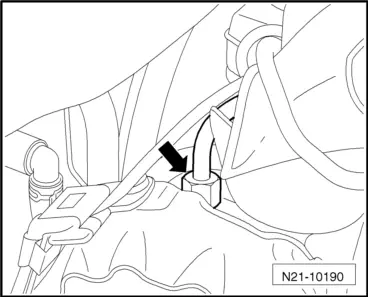

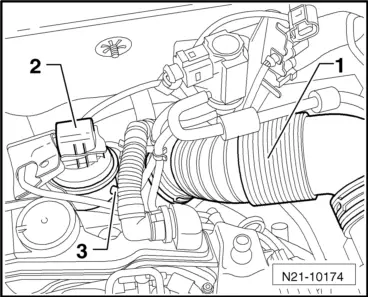

| Remove air filter housing with air mass meter and connecting pipe → Chapter. |

|

|

|

Note

Note

Note

Note

Caution

Caution