| t

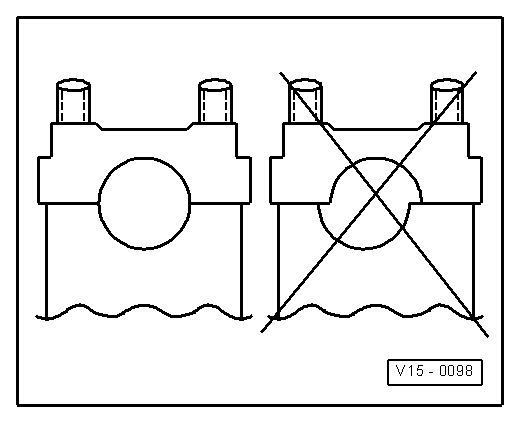

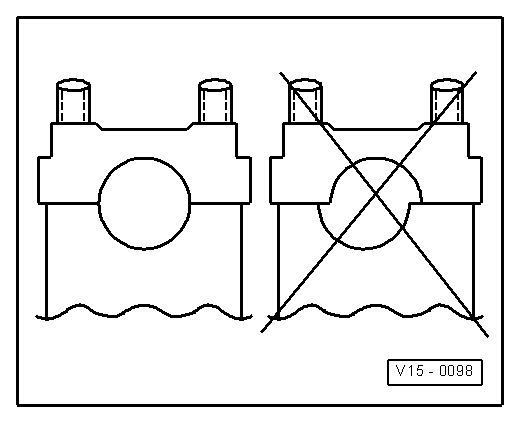

| When fitting the bearing caps, note the hole offset. Before fitting, position the bearing caps and determine the correct position. |

| –

| Oil running surfaces of both camshafts. |

| –

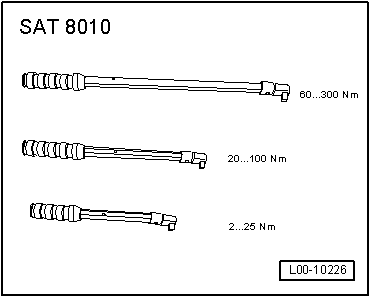

| Fit bearing caps 2 and 4 and tighten alternately in diagonal sequence. |

| –

| Apply a little sealant -AMV 174 004 01- to the touching surface of bearing caps 1 and 5. |

| –

| Fit bearing caps 3, 1 and 5 and tighten. |

| –

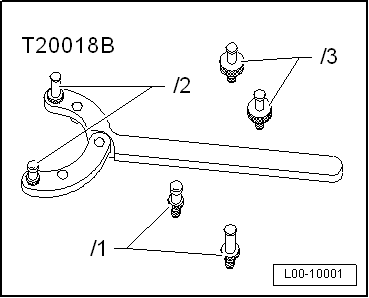

| Fit the camshaft sprocket. To tighten the bolt, immobilise the sprocket with the counterhold -T20018B-. |

Note | The crankshaft must not be at TDC when the camshaft is turned, as the valves or piston heads could be damaged. |

| Continue the fitting, following the reverse order of the removal process. |

Note | Engine is not to be started for approx. 30 minutes after fitting camshafts. The hydraulic compensation parts must settle (otherwise the valves would hit the pistons). |

|

|

|

Note

Note Note

Note

Note

Note Note

Note