| –

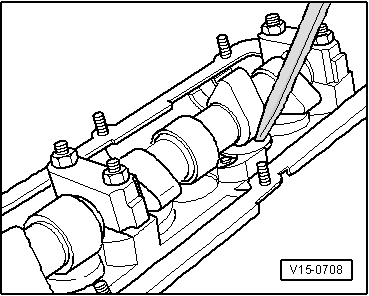

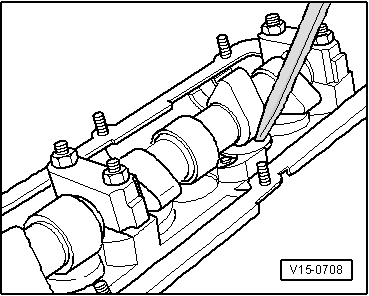

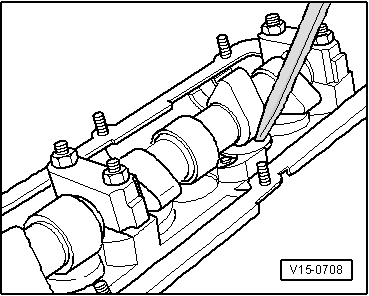

| Push the tappet down lightly with a wooden or plastic wedge. If it is possible to insert a 0.2 mm thick feeler gauge between the camshaft and the tappet, the latter should be replaced. |

Note | After fitting new tappets, the engine must not be started for approx. 30 minutes. The hydraulic valve compensation elements will have to settle (otherwise, the valves would strike the pistons). |

|

|

|

Note

Note Note

Note

Note

Note Note

Note