Leon Mk1

| Crankshaft: removing and installing |

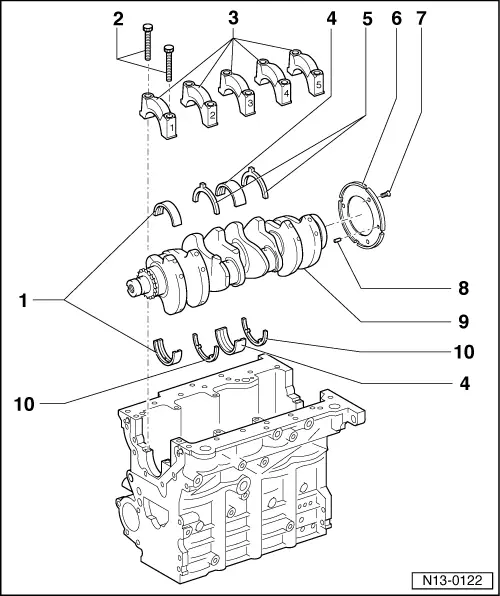

| 1 - | Bearing shells 1, 2, 4 and 5 |

| q | For bearing caps without oil groove |

| q | For cylinder block with oil groove |

| q | Do not mix up used bearing shells (mark them) |

| 2 - | 65 Nm + 1/4 turn (90 °) |

| q | Renew |

| q | To measure radial play tighten to 65 Nm, but do not re-tighten |

| 3 - | Bearing caps |

| q | Bearing cap 1: Pulley end |

| q | Bearing cap 3 with recesses for thrust washers |

| q | Bearing shell retaining lugs (cylinder block/bearing cap) must be on the same side |

| 4 - | Bearing shell 3 |

| q | For bearing cap without oil groove |

| q | For cylinder block with oil groove |

| 5 - | Thrust washer |

| q | For bearing cap 3 |

| q | Note fixing arrangement |

| 6 - | Sender wheel |

| q | For engine speed sender -G28- |

| 7 - | 10 Nm + 1/4 turn (90 °) |

| q | Renew |

| 8 - | Pin |

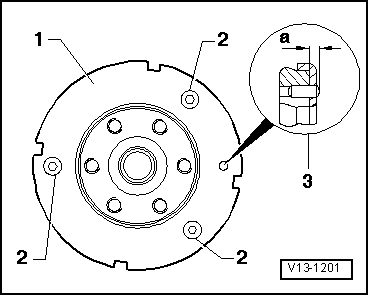

| q | Check the pin lug above the crankshaft → Fig. |

| 9 - | Crankshaft |

| q | Axial clearance, new: 0.07...0.17 mm Wear limit: 0.37 mm |

| q | Check radial clearance with Plastigage New: 0.03...0.08 mm Wear limit: 0.17 mm |

| q | Do not rotate the crankshaft when checking the radial clearance |

| q | Crankshaft dimensions → Chapter |

| 10 - | Thrust washer |

| q | For engine block, bearing 3 |