Leon Mk1

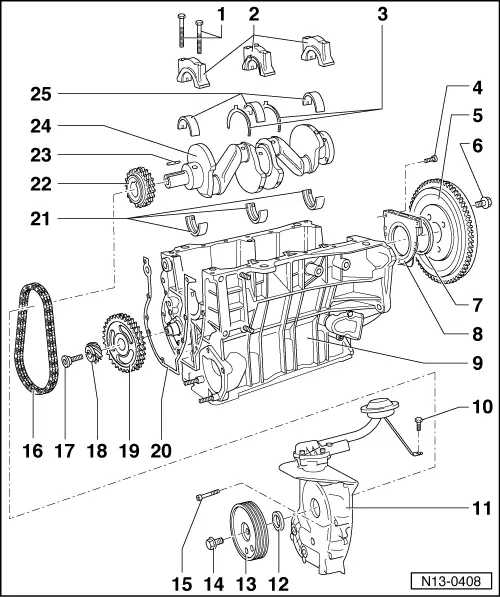

| Engine block, crankshaft, and flywheel: removing and installing |

| 1 - | 75 Nm |

| 2 - | Caps |

| q | Cap 1: pulley side |

| q | Cap 2: with holes for driving washers |

| 3 - | Driving washer |

| q | For cap 2 |

| q | Observe fitting |

| 4 - | 5 Nm |

| q | Fit with -AMV 188 001 02- |

| 5 - | Flywheel |

| q | Befor removal, mark the fitting position with the crankshaft |

| q | To remove and install the flywheel, immobilise it with special tool -T20075- and axle -T20075/1- |

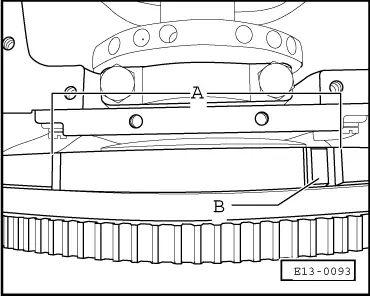

| q | When renewing, check the fitting position → Fig. |

| 6 - | 30 Nm + 1/4 turn (90°) |

| q | Renew |

| 7 - | O-ring |

| q | Renew |

| q | Remove the sealing flange and separate the retainer on the workbench |

| q | Before fitting, apply oil on the sealing lip and the outer edge |

| q | Insert in the sealing flange to the limit with -U-40052- |

| q | Fit sealing flange with hose -T20097- |

| 8 - | Sealing flange |

| q | Not supplied as a replacement part |

| q | Before fitting, apply -AMV 188 001 02- to it |

| 9 - | Engine block |

| q | Piston, connecting rod, and casing: removing and installing → Chapter |

| 10 - | 8 Nm |

| 11 - | Distribution cover |

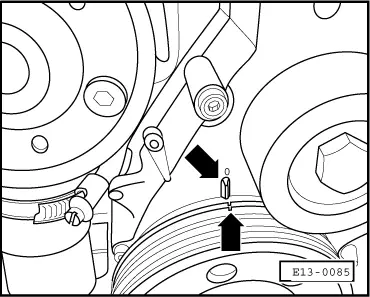

| q | TDC mark → Fig. |

| 12 - | Retainer |

| q | Renew → Chapter |

| 13 - | Pulley |

| q | Poly-V belt: removing and installing → Chapter |

| 14 - | 100 Nm |

| 15 - | 5 Nm |

| q | Fit with -D 000 600 A2- |

| 16 - | Double chain |

| q | Mark the turning direction (fitting position) before removing |

| 17 - | 25 Nm |

| q | Fit with -D 000 600 A2- |

| 18 - | Drive pinion |

| q | For driving oil pump |

| 19 - | Camshaft pinion |

| q | Camshaft adjustment → Fig. |

| 20 - | Gasket |

| q | Renew |

| 21 - | Half bearings |

| q | For engine block with lubrication groove |

| q | Do not interchange the used half bearings (mark them) |

| 22 - | Crankshaft pinion |

| q | Camshaft adjustment → Fig. |

| 23 - | Cotter pin |

| q | Make sure it lies properly |

| 24 - | Crankshaft |

| q | Ø Bed plate bearing journals: 60 mm Ø Connecting rod bearing journals: 42 mm |

| q | Axial play, new: 0.03...0.13 mm Wear limit: 0.26 mm |

| q | Measure the radial play with Plastigage New: 0.02...0.07 mm Wear limit: 0.13 mm |

| q | Do not turn crankshaft while measuring radial play |

| 25 - | Half bearing |

| q | For cap without lubrication groove |

| q | Do not interchange the used half bearings (mark them) |

|

|

|

|