WARNING | Important information for using an engine with one of the designated spare parts (replacement engine): |

| t

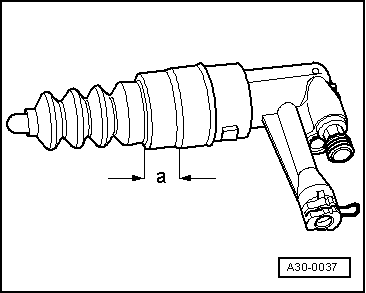

| Take note that the roller tappet is not included in the scope of supply of the new replacement engine. |

| t

| When exchanging the replacement engine, the roller tappet has to be used, if this is possible. |

| t

| The following parts will be influenced if the roller tappet is not installed: Camshaft, high-pressure pump and cylinder head cover. |

| t

| The cylinder head may also be influenced as a result of damage to the bolt of the high-pressure pump. |

| t

| The engine will be damaged permanently if the valves make contact with the piston. |

|

| Installation is carried out in reverse order, noting the following: |

Note | t

| When fitting, replace the self-locking nuts and bolts. |

| t

| Renew bolts which have a specified tightening angle, as well as seals and gaskets. |

| t

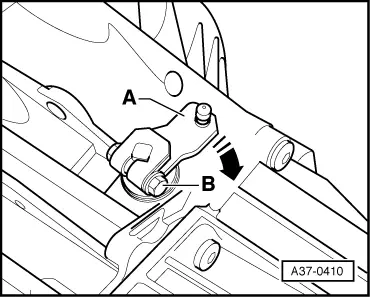

| Secure all hose connections with the correct hose clips (same as original equipment) → Parts catalogue. |

| t

| Clean input shaft splines and, for used clutch plates, hub splines; remove corrosion and apply a thin coat of grease → Parts Catalogue to the splines. Then move the clutch plate on the input shaft from side to side, until the hub moves smoothly on the shaft. Excess grease must be removed. |

| For vehicles with automatic Gearbox |

| –

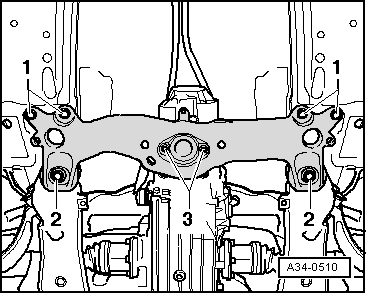

| Install the engine / gearbox assembly with mounted particulate filter. |

| Continued for all vehicles |

| –

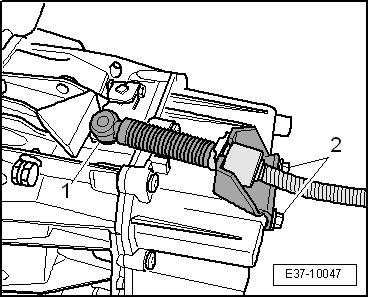

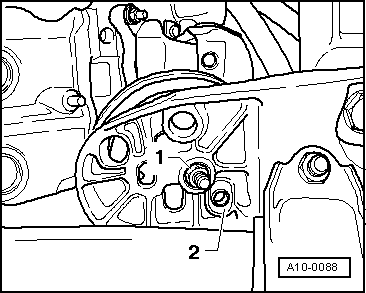

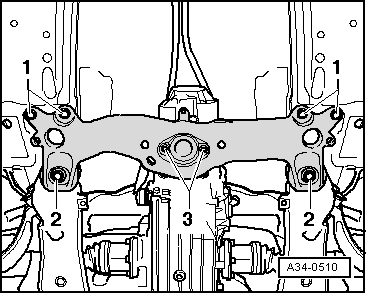

| Lower engine and gearbox and simultaneously guide stud bolt on left mount into console. Then install the left mount. |

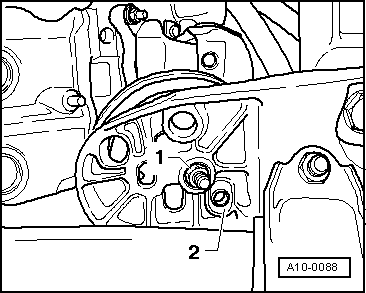

Note | Use vehicle jack to align engine/transmission unit and position in rear area of transmission. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note Note

Note

Note

Note Note

Note

Note

Note