| –

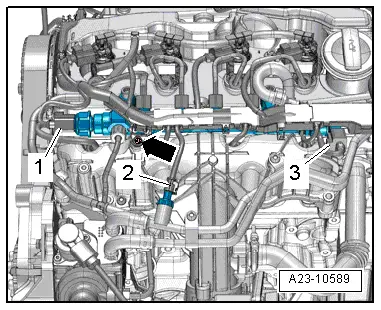

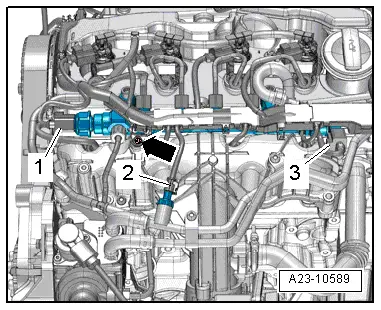

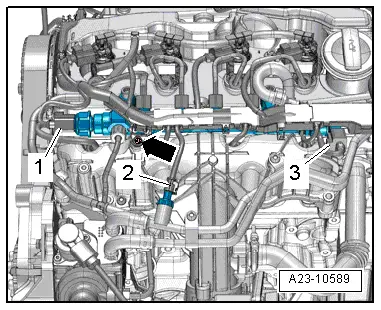

| Unplug electrical connector -1- at fuel pressure sender -G247-. |

| –

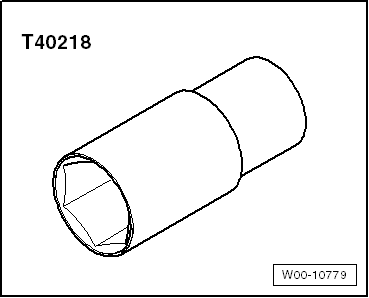

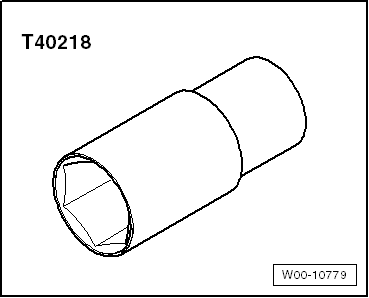

| Unscrew fuel pressure sender -G247- using socket, 27 mm -T40218-. |

Note | An open-end spanner must not be used for loosening or tightening. |

| –

| Suction out the dirt from the opening of the high pressure tank (thread and sealing surface). Do not use metal tools, etc. |

Note | t

| The fuel pressure sender -G247- has no sealing ring, but a deformable metal sealing. |

| t

| Note damage of the sealing surfaces (bite-edge sealing) and thread of the newfuel pressure sender -G247- . If the fuel pressure sender -G247- was inspected and is in order, another reuse is possible. |

| t

| Also check the sealing surface on the borehole of the high-pressure reservoir. |

| t

| Start of thread and deformable sealing lip of fuel pressure regulating valve -G247- must be moistened with diesel. |

| –

| Tighten the fuel pressure sender -G247- by hand. |

| –

| Subsequently tighten the fuel pressure sender -G247- on the prescribed tightening torque. |

| –

| After installing fuel pressure sender -G247-, leave engine running at moderate speed for a few minutes when bleeding fuel system and then switch off again. |

Note | The high-pressure connections must „not“ be opened for bleeding; fuel system bleeds itself automatically. |

| –

| Interrogate fault memory and erase, if necessary. |

| –

| Carefully check the entire fuel system for leaks. |

| Renew affected component if leakage still occurs after tightening to correct torque. |

| –

| After completing the repair, road-test the vehicle. Accelerate with full throttle at least once. Then check the high-pressure section of the fuel system again for leaks. |

Note | If there is any air left in the fuel system, the engine may switch to the backup mode ('emergency running' mode) during the road test. Switch off the engine and erase the fault memory. Then continue road test. |

| –

| After road test interrogate the fault memory again. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note Note

Note