Leon Mk1

|

| Special tools and workshop equipment required |

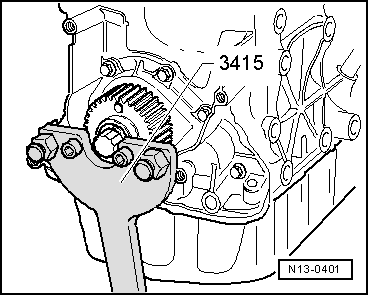

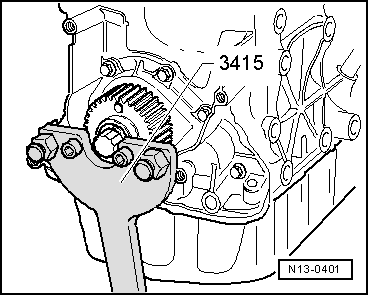

| t | Hose clamp -3415-, see equivalent → Anchor |

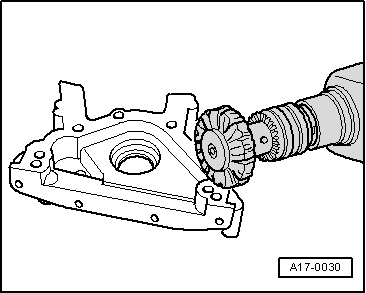

| t | Mounting tool -T10053-, see equivalent → Anchor |

| t | Torque wrench (5 - 50 Nm) -V.A.G 1331-, see equivalent → Anchor |

| t | Torque wrench (40 - 200 Nm) -V.A.G 1332-, see equivalent → Anchor |

| t | Electric drill with plastic brush attachment |

| t | Flat scraper |

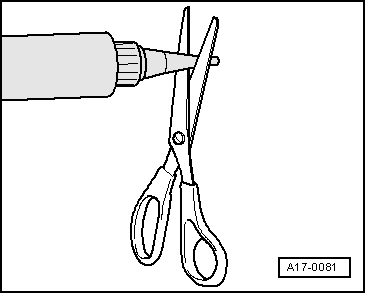

| t | Silicone sealant → Spare parts catalogue |

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm | |

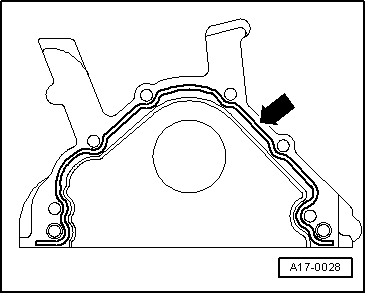

| Sealing flange to cylinder block | 15 |

WARNING

WARNING