Leon Mk1

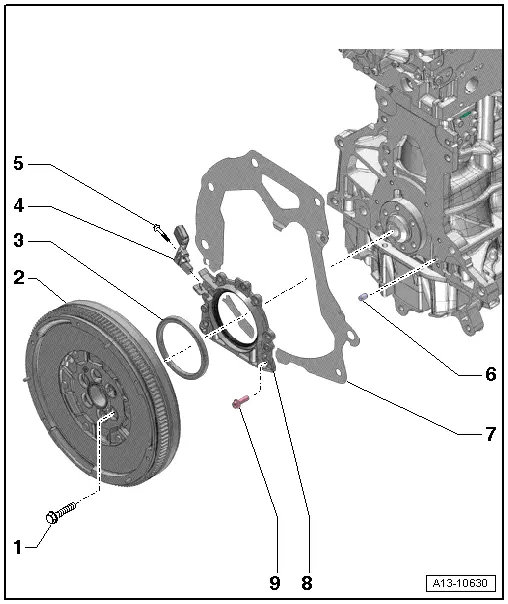

| Sealing flange, gearbox side and dual-mass flywheel: Assembly overview |

| 1 - | 60 Nm ± +90° |

| q | Renewing |

| 2 - | Dual-mass flywheel |

| q | Removing and installing → Chapter |

| q | Can only be installed in one position (as the holes are off-set) |

| 3 - | Generator wheel: |

| q | For engine speed sender -G28- |

| 4 - | Engine speed sender -G28- |

| q | Removing and installing → Chapter |

| 5 - | 5 Nm |

| 6 - | Locking tool |

| q | 2 units |

| 7 - | Intermediate plate |

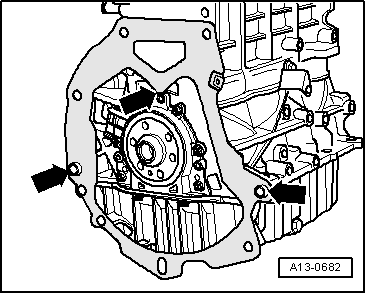

| q | Do not damage / bend when assembling → Fig. |

| 8 - | Sealing flange on flywheel side |

| q | With seal |

| q | Renew → Chapter |

| 9 - | Bolt |

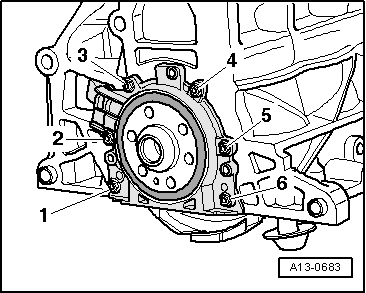

| q | Specified torques and installation sequence → Fig.. |

|

|

|

|

| stage: | Bolts | Specified torque |

| 1. | -1 … 6- | Screw in by hand until they make contact |

| 2. | -1 … 6- | Tighten in stages and in diagonal sequence; final torque 15 Nm. |

Note

Note

|