| t

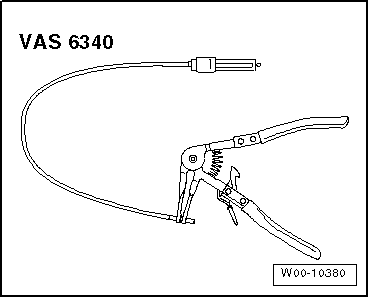

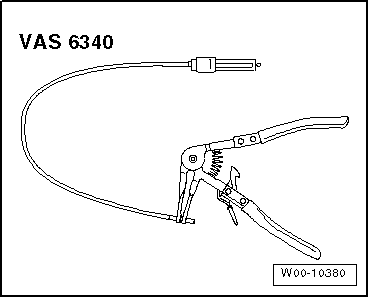

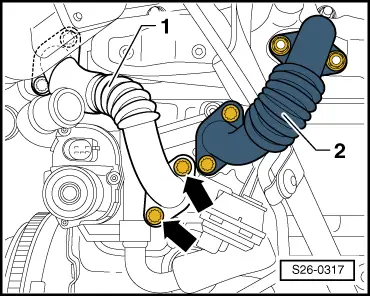

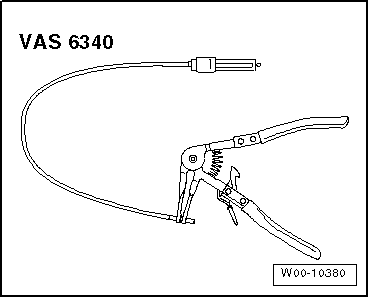

| Pliers for spring-loaded band-type clamps -VAS 6340-, see equivalent → Anchor |

| t

| Torque wrench (5 - 50 Nm) -V.A.G 1331-, see equivalent → Anchor |

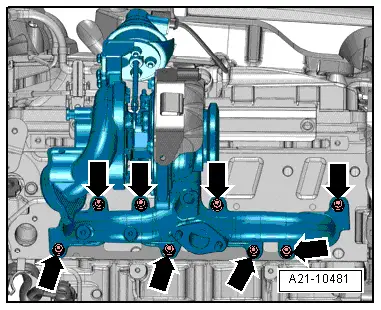

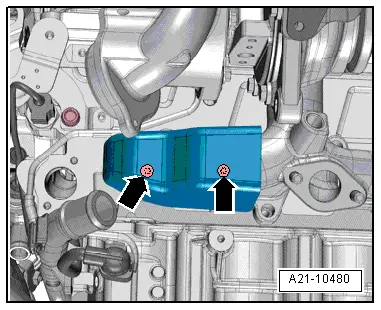

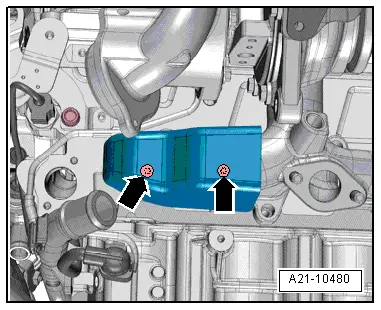

Note | When fitting the heat protection plate, fit to the same location. |

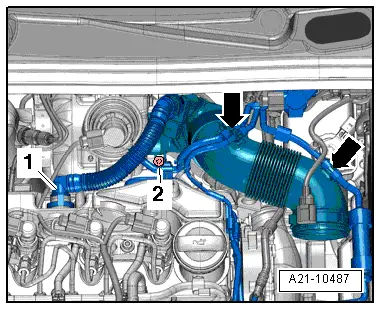

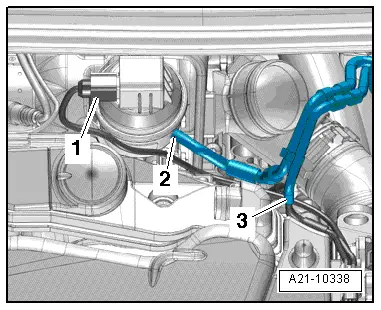

Caution | If a mechanical fault is discovered on the turbocharger (e.g. a destroyed compressor impeller), it is not sufficient to just renew the turbocharger. To avoid any subsequent damage, the following work must be carried out: |

| t

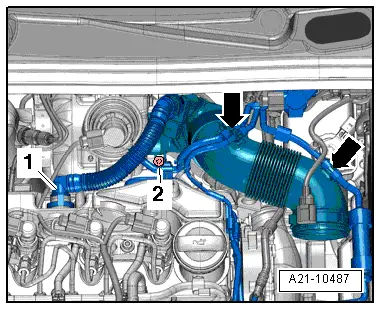

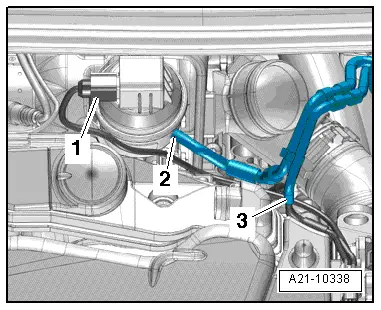

| Check air filter housing, air filter element and air inlet hoses for contamination. |

| t

| Check the process of the charge air circuit and the charge air cooler for foreign particles. |

| t

| If foreign objects are discovered in the charge air system, clean the charge air path and, if necessary, renew the charge air cooler. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note