| –

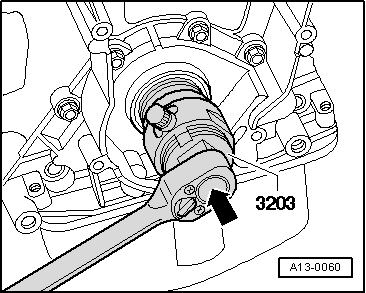

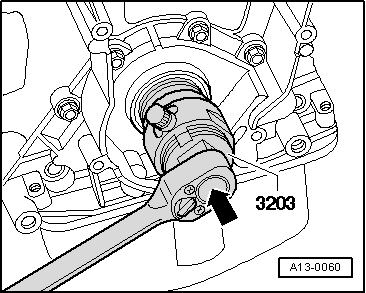

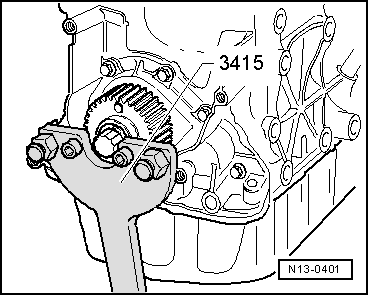

| Lubricate threaded head of oil seal extractor -3203-, place it in position and, while exerting firm pressure, screw it into oil seal as far as possible. |

| –

| Loosen knurled screw and turn inner part against crankshaft until the oil seal is pulled out. |

| –

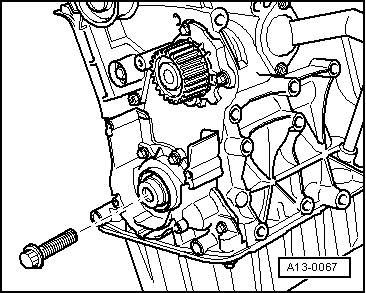

| Clamp the gasket extractor in a vice at the flat edges and remove the gasket with pliers. |

| Reassembly is carried out in the reverse order; note the following: |

| –

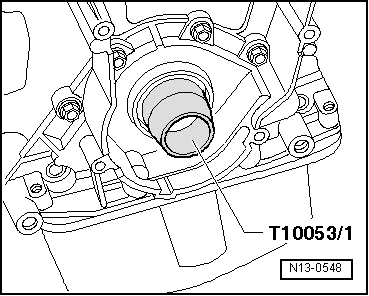

| Clean contact surface and sealing surface. |

| –

| Use clean cloth to wipe off oil residue at crankshaft journal. |

|

|

|

Note

Note