Leon Mk1

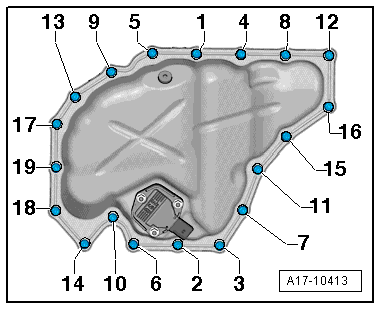

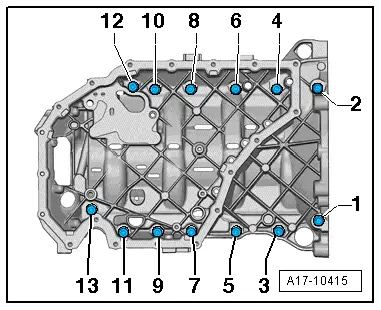

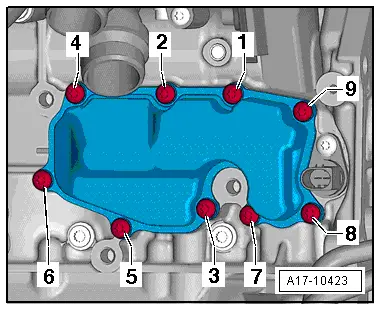

| Sump, oil pump - exploded view |

| 1 - | Oil level/oil temperature sender -G266- |

| 2 - | Seal |

| q | Replace |

| 3 - | Bolt. |

| q | Replace |

| q | Tightening sequence → Fig. |

| 4 - | Sump (bottom section) |

| q | Removing and installing → Chapter |

| 5 - | Anti-surge valve |

| q | Replace |

| 6 - | Oil intake pipe |

| q | Clean strainer if dirty |

| 7 - | Bolt. |

| q | 9 Nm |

| 8 - | O ring |

| q | Replace |

| q | Lubricate |

| 9 - | Oil pump: |

| q | Removing and installing → Chapter |

| 10 - | Centring sleeve |

| 11 - | O ring |

| q | Replace |

| 12 - | Valve for oil pressure control -N428- |

| q | Removing and installing → Chapter |

| 13 - | Bolt. |

| q | 9 Nm |

| 14 - | Chain tensioner |

| 15 - | Drive chain for oil pump |

| q | Mark direction of rotation before removing |

| 16 - | Bolt. |

| q | 9 Nm |

| 17 - | Seal |

| q | Replace |

| 18 - | Coarse oil separator |

| q | Removing and installing → Chapter |

| 19 - | Bolt. |

| q | Tightening sequence → Fig. |

| 20 - | Sump (top section) |

| q | Removing and installing → Chapter |

| 21 - | Bolt. |

| q | Replace |

| q | Tightening sequence → Fig. |

| 22 - | Bolt. |

| q | Replace |

| q | Tightening sequence → Fig. |

| 23 - | Bolt. |

| q | 20 Nm |

| 24 - | Seal |

| 25 - | Bolt. |

| q | 9 Nm |

| 26 - | Seal |

| 27 - | Retaining valve |

| 28 - | Oil drain plug |

| q | Replace |

| q | 30 Nm |

| 29 - | Nut |

| q | 9 Nm |

|

|

|

|

|

|