Note | t

| To carry out this work it will be necessary to disconnect battery earth strap. Therefore check whether a coded radio is fitted. Where necessary, check the anti-theft coding first. |

| t

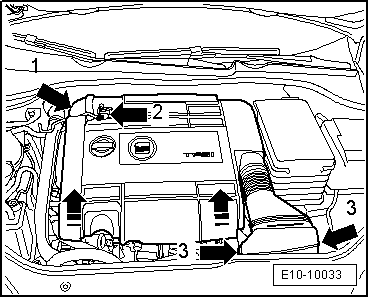

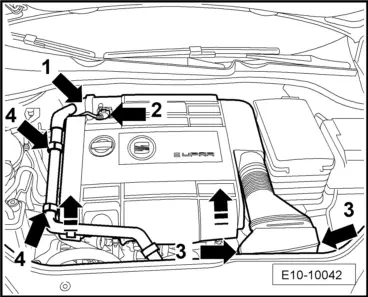

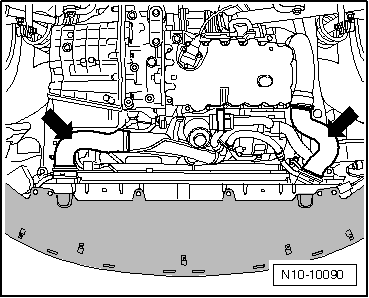

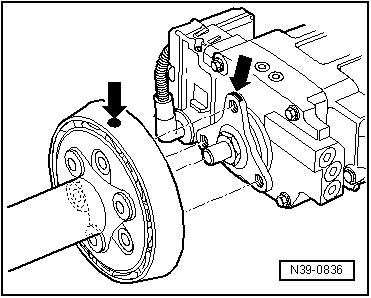

| The engine is removed from underneath together with the gearbox. |

| t

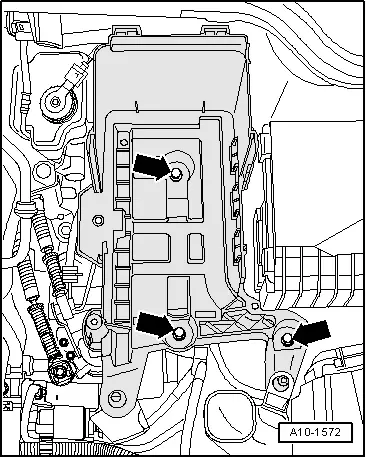

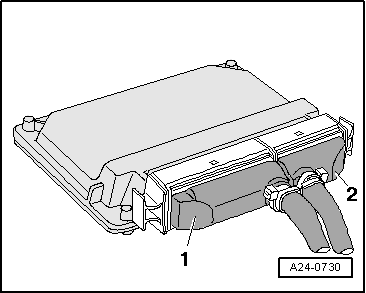

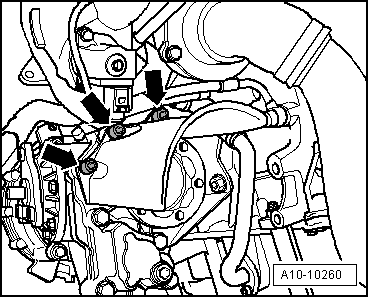

| All the cable fixings that are opened or cut during removal of the cylinder head must be fitted in the same position when reinstalling the engine. |

Caution | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

| Route all the various lines (e.g. for fuel, hydraulics, active carbon filter system, coolant, refrigerant, brake fluid and vacuum pipes and hoses) and electrical wiring so that the original positions are restored. |

| t

| In order to prevent damage to the pipes all moving or hot parts must be easily accessible. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING