| t

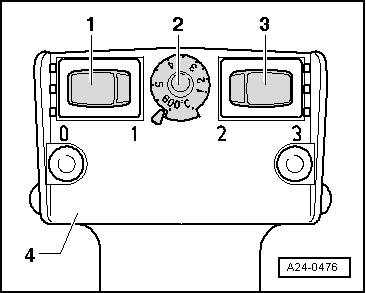

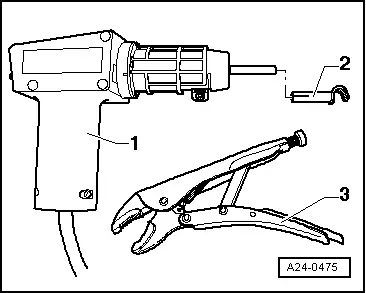

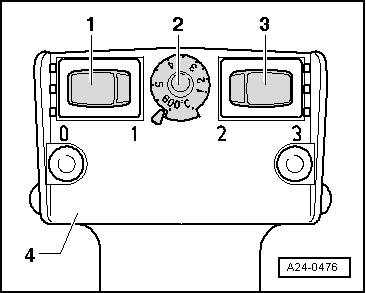

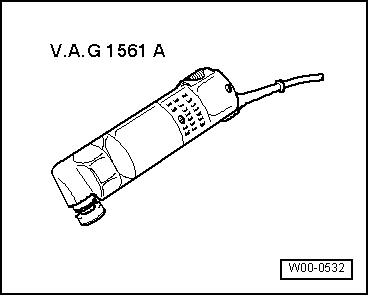

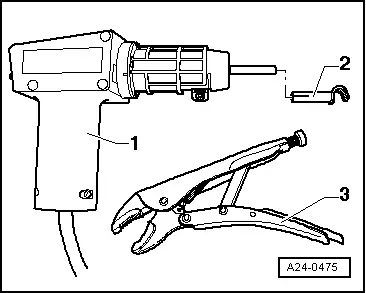

| Hot-air gun -1- from the cable repair kit -VAS 1978A- |

| t

| Connectable nozzle -2- (also from the cable repair kit -VAS 1978A-) |

| t

| Self-locking pliers, sold commercially (gripping jaws) -3- |

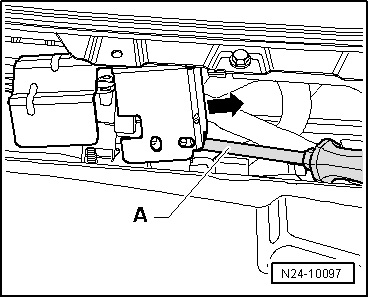

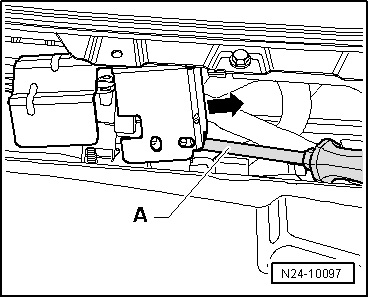

Note | To replace the engine control unit, connect the central diagnosis -VAS 5051B- or central diagnosis -VAS 5052- and complete the guided function “Replace control unit”. |

| –

| Switch off ignition and remove key. |

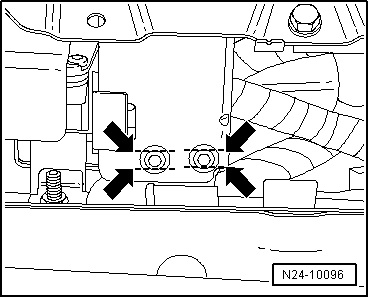

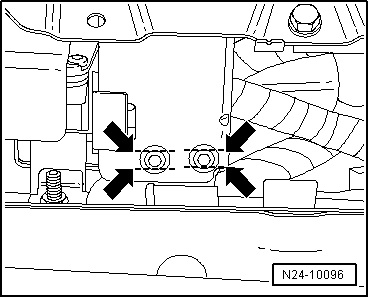

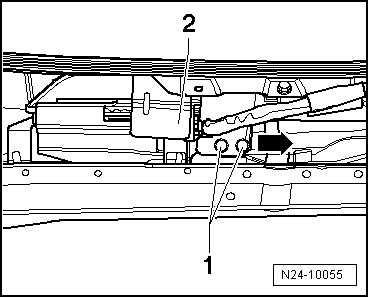

Note | The thread on the breakaway bolts has been treated with a threadlocker. The effect of the threadlocker is reduced by heating the breakaway bolts with a hot air gun. |

WARNING | It is essential to prevent damaging (burning) cables and connectors, insulation and control units, therefore, the procedure below must be followed exactly. Remember the instructions for using the hot-air gun. |

|

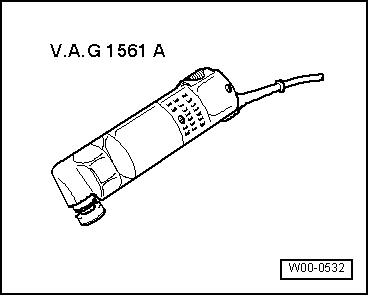

| Carry out the adjustments on the hot air blower -4- as described below: |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note