| t

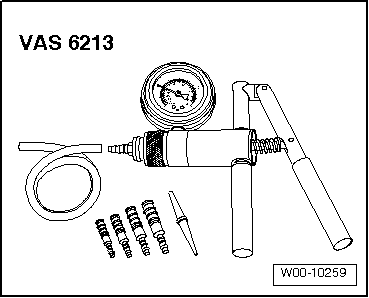

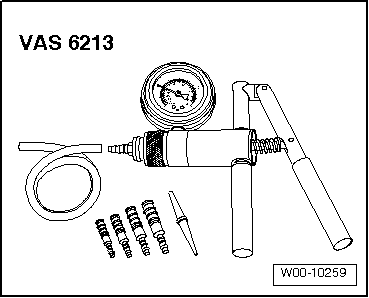

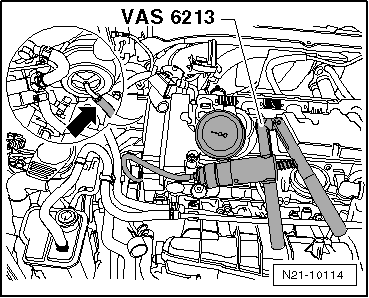

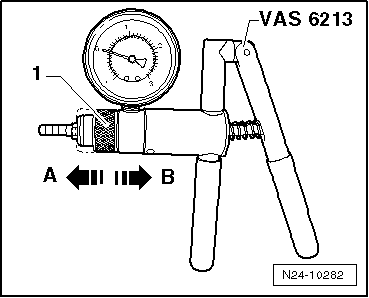

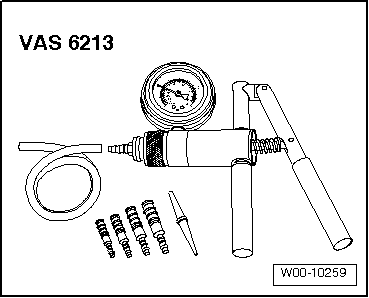

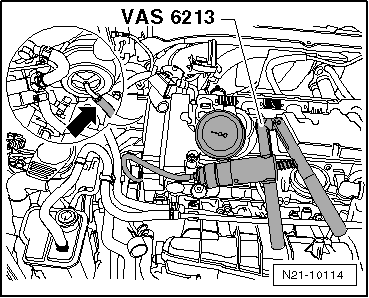

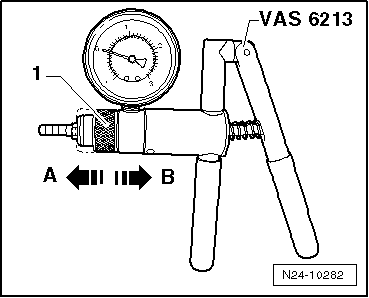

| Manual vacuum pump -VAS 6213-, see equivalent → Anchor |

| t

| Engine oil temperature at least. 60 °C |

| t

| Vehicles with direct transmission: the selector lever must be in position. “P” |

| t

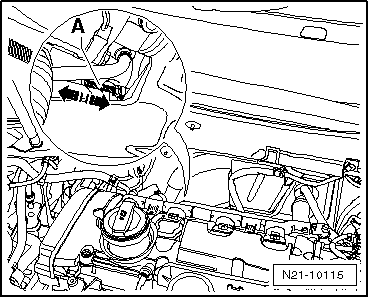

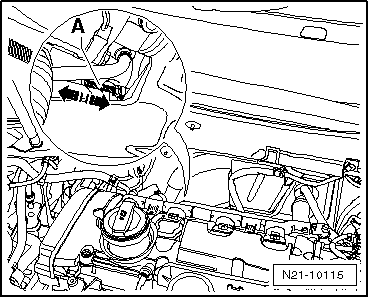

| The turbocharger hose, which leads from the supercharger pressure limitation solenoid valve -N75- to the pressure capsule, must have flow continuity |

| t

| Supercharger pressure limitation solenoid valve -N75-: OK |

| t

| The exhaust system must be free of leaks |

| –

| Remove the engine cover / air filter → Chapter. |

|

|

|

Note

Note

Note

Note