Leon Mk1

| balance shaft chain - Assembly overview |

| 1 - | Bolt. |

| q | Replace |

| q | 9 Nm. |

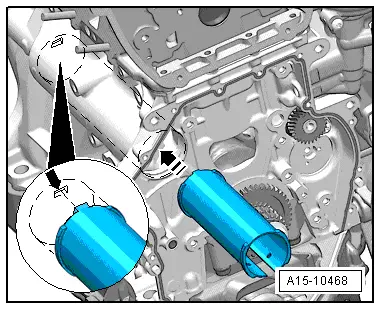

| 2 - | Balancing shaft |

| q | Exhaust side |

| q | Must be renewed if removed |

| q | Lubricate the mount with engine oil |

| q | Removing → Chapter |

| 3 - | Balance shaft tube |

| q | Installation position → Fig. |

| 4 - | Chain tensioner |

| q | 65 Nm. |

| 5 - | cylinder block |

| 6 - | Balancing shaft |

| q | Inlet side |

| q | Lubricate the mount with engine oil |

| q | Removing → Chapter |

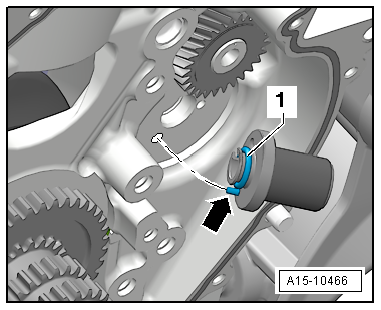

| 7 - | O ring |

| q | Lubricate with engine oil |

| 8 - | Bearing pin |

| q | Lubricate with engine oil |

| q | Installation position → Fig. |

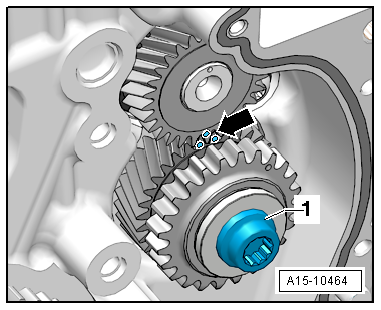

| 9 - | Intermediate chain pinion |

| q | for balance shaft |

| q | If bolt → Item was slackened, idler gear must be renewed |

| 10 - | Bolt. |

| q | Replace |

| q | 9 Nm. |

| 11 - | Washer |

| 12 - | Bolt. |

| q | If the bolt was slackened, the timing chain sprocket must be replaced → Item |

| q | Tightening sequence → Fig. |

| 13 - | Lower runner |

| q | For the balance shaft chain |

| 14 - | Guide pin |

| q | 20 Nm. |

| 15 - | Tensioning plate |

| q | For timing chain |

| 16 - | Guide pin |

| q | 20 Nm. |

| 17 - | balance shaft chain |

| q | Removing → Chapter |

| 18 - | Pinions |

| q | Installation position → Fig. |

| 19 - | Upper runner |

| q | For the balance shaft chain |

| 20 - | Guide pin |

| q | 20 Nm. |

|

|

|

|

Caution

Caution