| –

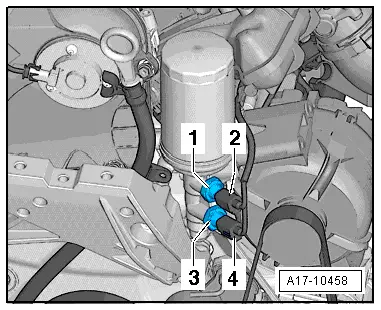

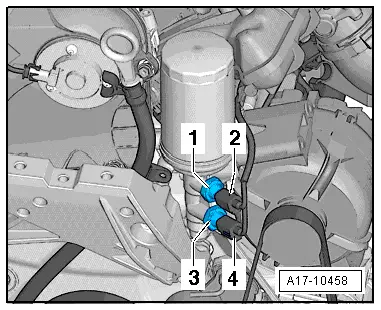

| Unplug electrical connector -2- at oil pressure switch for reduced oil pressure -F378-. |

| –

| Unscrew oil pressure switch for reduced oil pressure -F378--1-. |

| –

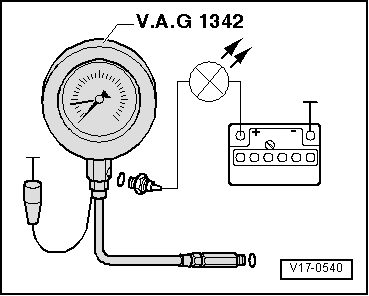

| Screw oil pressure tester -V.A.G 1342- into oil filter bracket in place of oil pressure switch. |

| –

| Screw in the oil pressure switch for reduced oil pressure -F378- into the pressure gauge -V.A.G 1342-. |

| l

| Oil pressure at engine idle: min. 1,2 ... 2.1 bar |

| l

| Oil pressure at 2,000 rpm: 1,6 ... 2.1 bar |

| l

| Oil pressure at 3,700 rpm: 3,0 ... 4.0 bar |

Note | During the first 1000 km, the oil pressure at 2000 rpm can be between 3.0 and 4.0 bar. |

| If the specifications are not met: |

| –

| Check if the strainer in the oil suction pipe is dirty → Item. |

Note | Insufficient oil pressure may also be caused by mechanical faults, e.g. damaged bearings. |

| Check the Oil pressure switch for reduced oil pressure -F378- (brown): |

|

|

|

Note

Note Note

Note

Note

Note Note

Note