| –

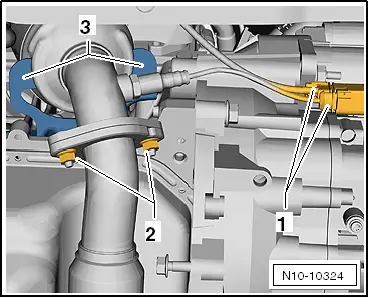

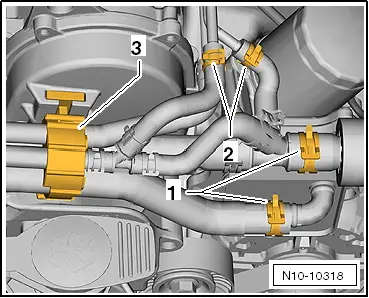

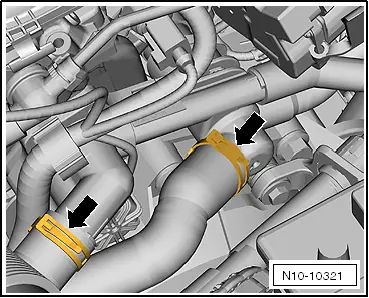

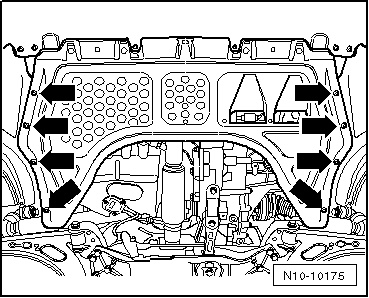

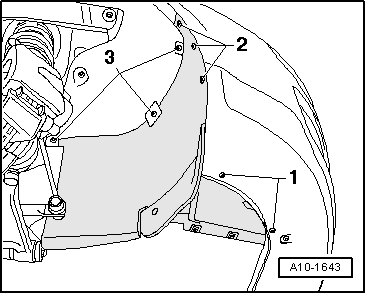

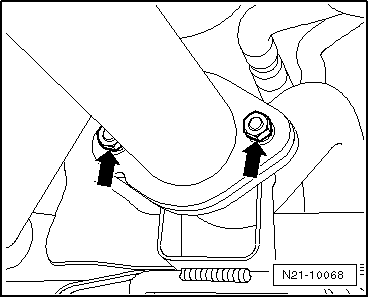

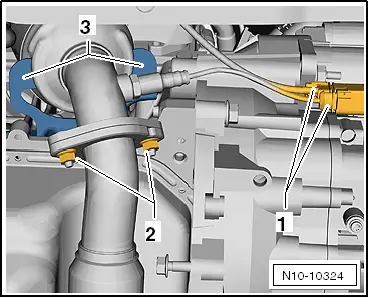

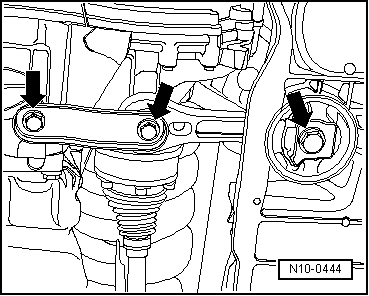

| Unscrew the securing nuts -2- and press the exhaust pipe to the back using an assembly lever in order to remove it from the rubber mountings. |

| –

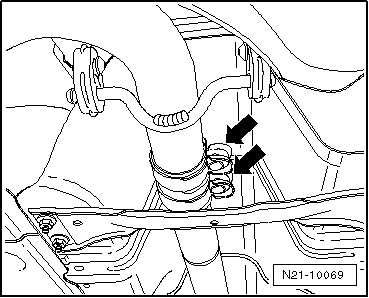

| Withdraw the exhaust pipe towards the front. |

| –

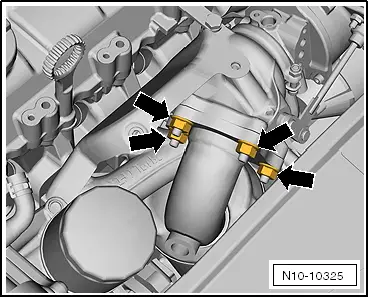

| Undo the securing nuts -3- and remove the catalytic converter downwards. |

| –

| All the cables, that are opened or cut during dismounting, should be placed again in the same location previously occupied during the fitting. |

| –

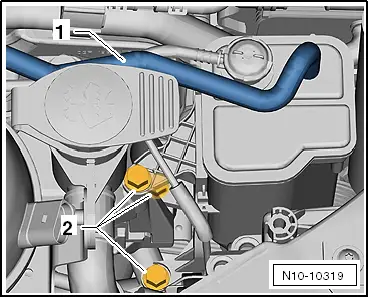

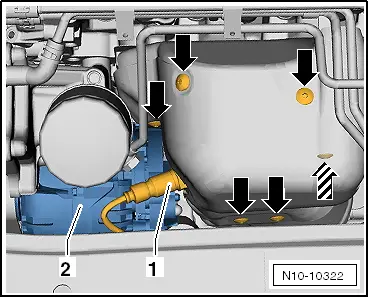

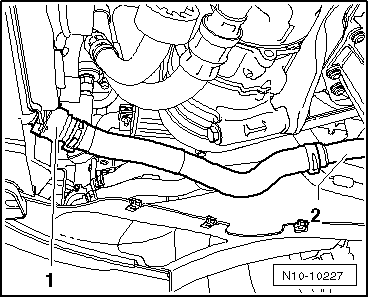

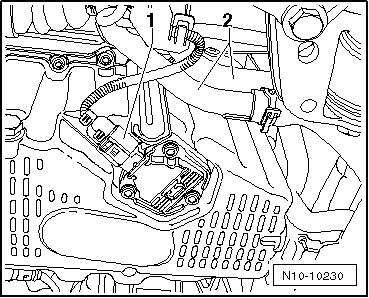

| Remove all of the electrical cables from the gearbox, alternator, and starter motor leaving them uncovered. |

| –

| Pull off or disconnect all other electrical connections as necessary from engine and lay to side. |

| –

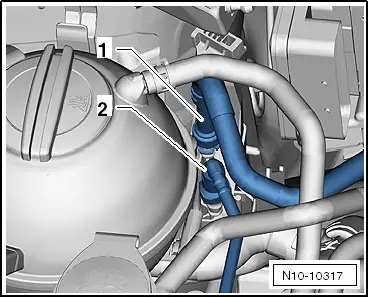

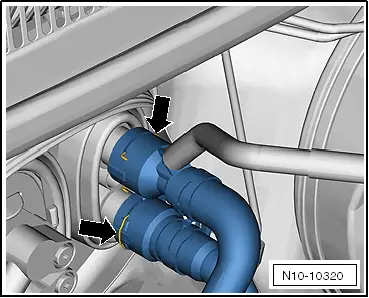

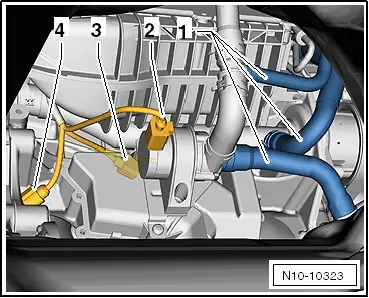

| Pull vacuum and breather hoses off engine. |

| –

| Pull connector off thermo-switch and radiator fan. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note

WARNING

WARNING Caution

Caution