| –

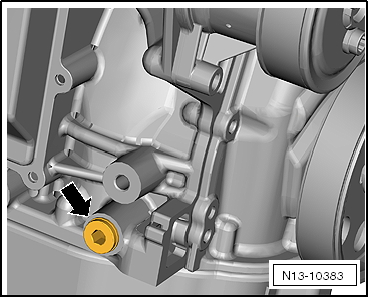

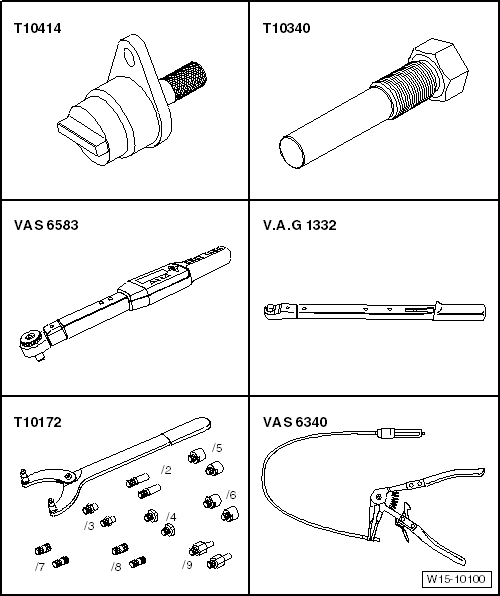

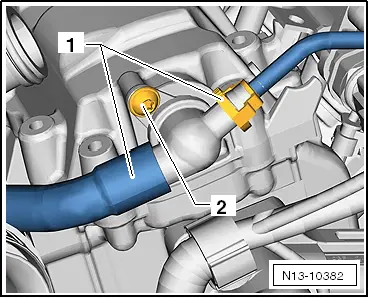

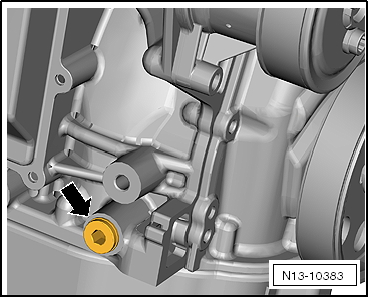

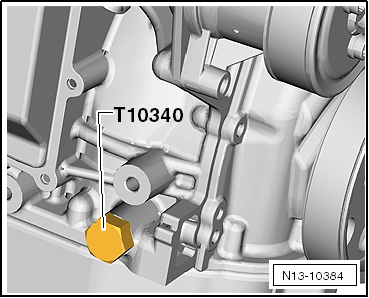

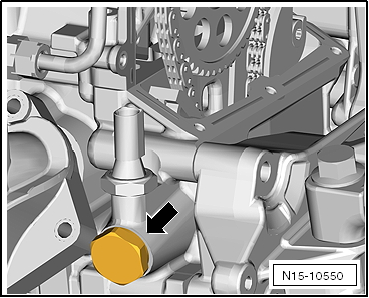

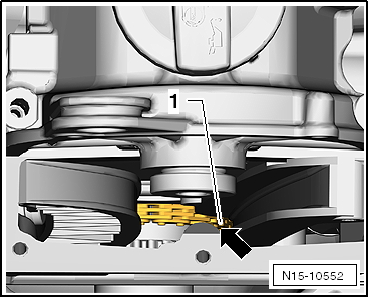

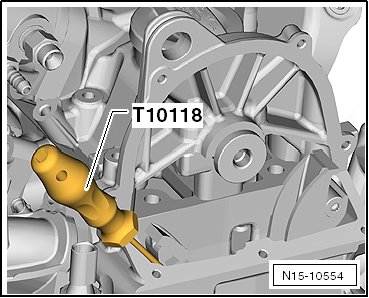

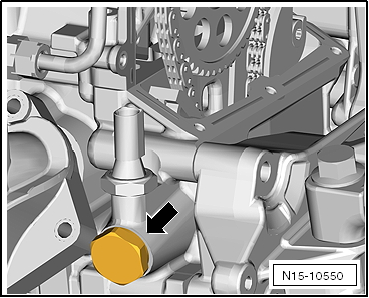

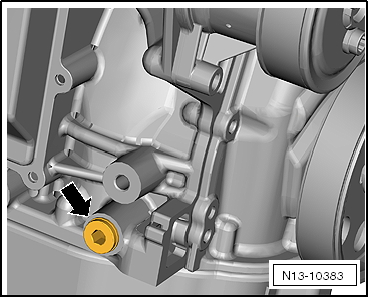

| Unscrew the sealing plug -arrow- from the cylinder block. |

| –

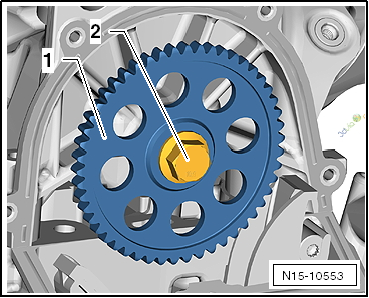

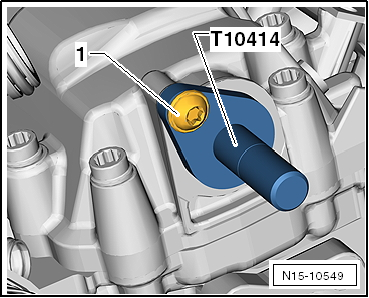

| Screw in the locking bolt -T10340- to the end of the cylinder block. |

Caution | If the locking bolt -T10340- cannot be screwed until the end point, the crankshaft is not in the right position. |

| In this case, proceed as follows: |

|

| –

| Remove the locking pin. |

| –

| Turn the crankshaft by a 1/4 90° rotation in the direction of the operation of the engine. |

| –

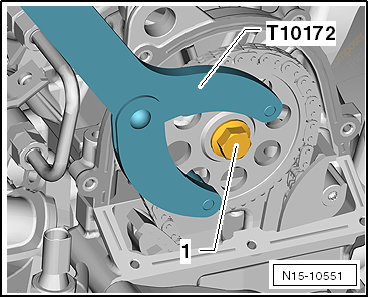

| Tighten the securing screw -T10340- until the end point in the crankshaft sump. |

| –

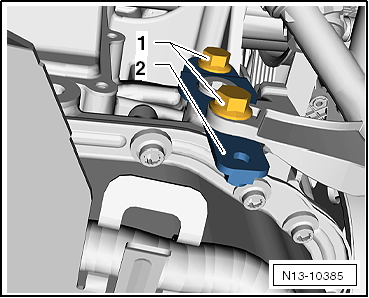

| Tighten the securing bolts securing bolts -T10340- to 30 Nm. |

| –

| Turn the crankshaft to the end point in the direction of the operation of the engine. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution