Leon Mk1

|

|

|

|

|

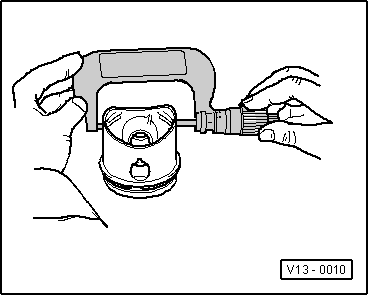

| Piston ring Dimensions in mm | When new | Wear limit |

| 1. compression ring | 0,20 … 0,40 | 1,0 |

| 2. compression ring | 0,40 … 0,60 | 1,0 |

| Oil scraping ring | 0,25 … 0,75 | ---1) |

|

|

|

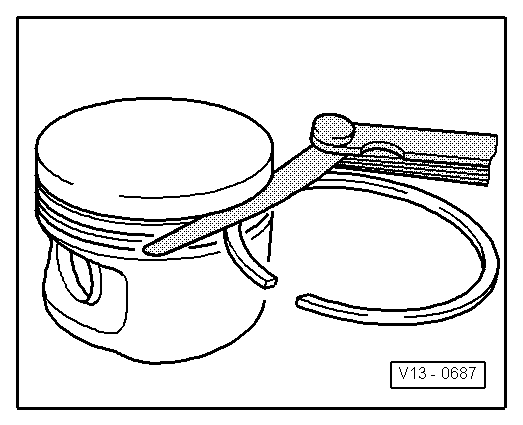

| Piston ring Dimensions in mm | When new | Wear limit |

| 1. compression ring | 0,03 … 0,09 | 0,15 |

| 2. compression ring | 0,02 … 0,06 | 0,15 |

| Oil scraping ring | Not measurable | |

|

Note

Note

|

|