| –

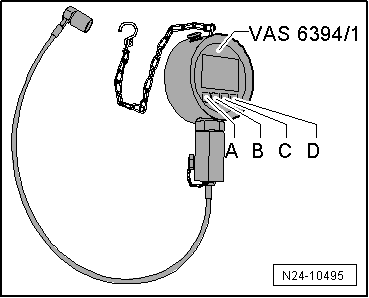

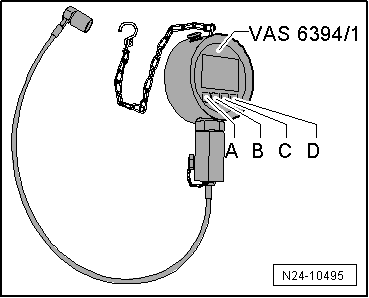

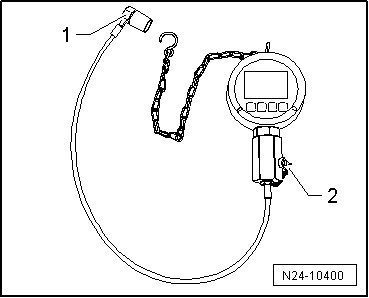

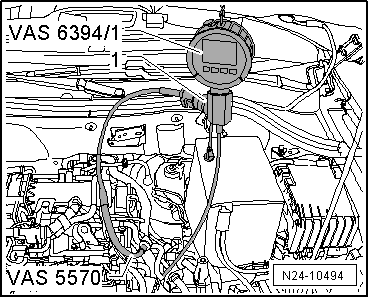

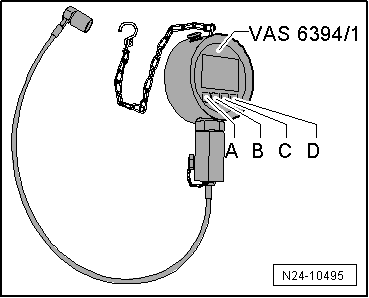

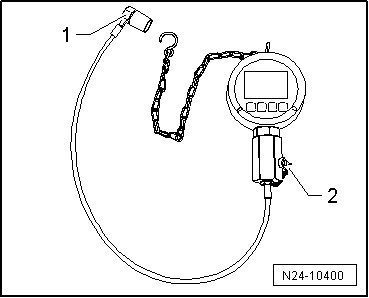

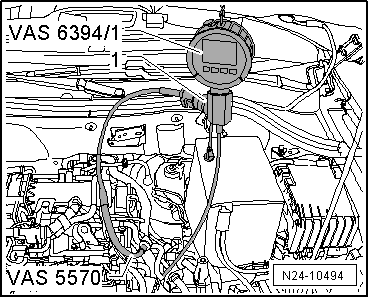

| Switch on digital pressure gauge -VAS 6394/1- by pressing key -A- briefly once. |

Note | When button -A- is pressed for 2 seconds, the illumination will be switched on for 20 seconds. |

| Digital pressure gauge -VAS 6394/1- should display 0 bar; if this is not the case, press key -C- briefly once for zero point compensation. |

| –

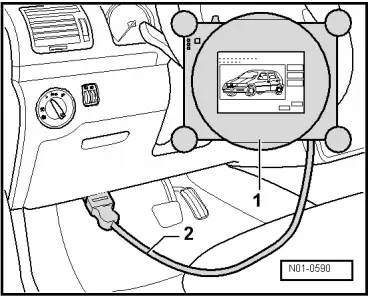

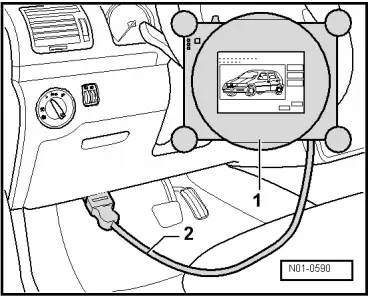

| Compare pressure displayed by digital pressure gauge -VAS 6394/1- with actual value of vehicle diagnosis, testing and information system -VAS 5051B-. |

| The pressures may deviate by up to 5 bar. |

| If pressures do not correspond, fuel pressure sender -G247- must be renewed. |

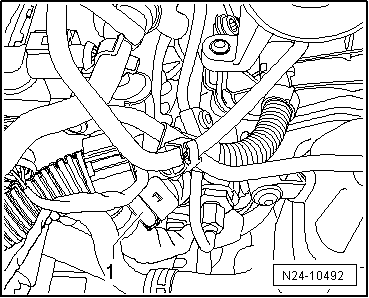

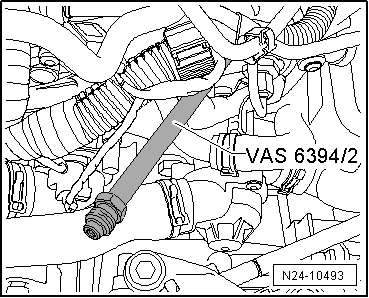

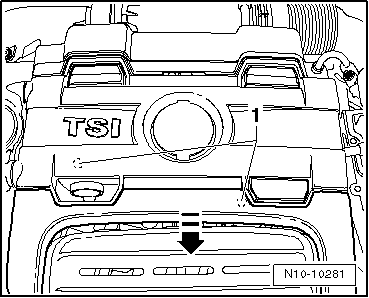

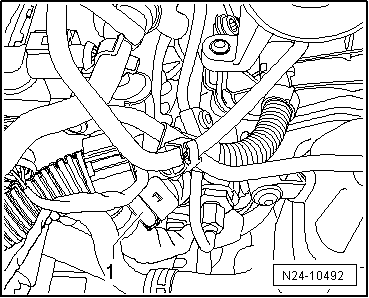

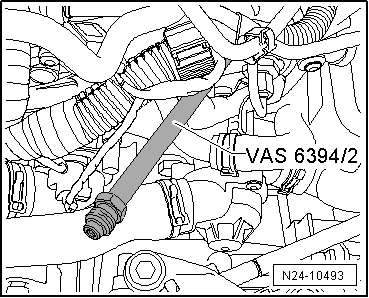

WARNING | The injection system is sub-divided into a high pressure system (max. approx. 120 bar) and a low pressure system (approx. 6 bar). |

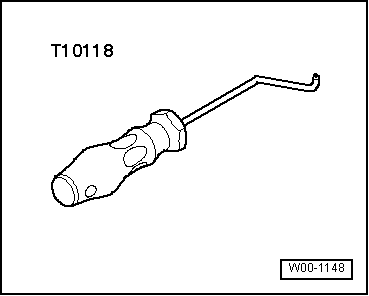

| Prior to opening the high-pressure area, e.g. when removing the high-pressure pump, fuel rail, injectors, a fuel line, or the fuel pressure sender -G247-, the fuel pressure in the high-pressure area must be reduced to a residual pressure of approx. 6 bar. The appropriate procedure is described in the chapter on releasing pressure in the high-pressure section → Chapter. |

|

Note | Once the high-pressure in the high-pressure area is reduced, open the system immediately as the pressure will rise again due to warming. |

| –

| Renew fuel pressure sender -G247- and again compare both measured values. |

| If measured values again fail to correspond: |

| If measured values correspond: |

|

|

|

Note

Note Note

Note

Note

Note Note

Note